-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-23 Views:1

Aluminum - based PCBs (Printed Circuit Boards) have emerged as a specialized and highly valuable solution in the realm of electronics, particularly in applications where efficient heat dissipation is of critical importance. Unlike traditional PCBs that primarily focus on electrical connectivity, aluminum - based PCBs leverage the excellent thermal conductivity of aluminum to address the heat management challenges associated with high - power electronic devices.

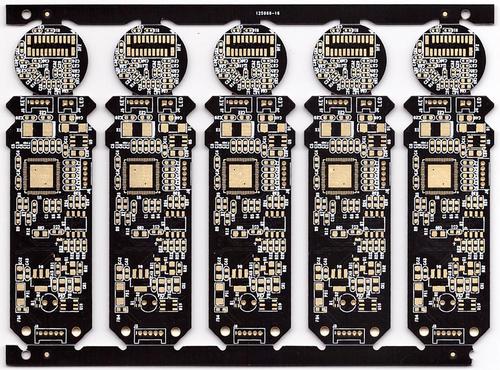

The structure of an aluminum - based PCB typically consists of three main layers: a top copper layer for electrical traces, a middle aluminum core layer for heat dissipation, and a bottom insulating layer. The top copper layer is where the electrical circuits are printed, similar to conventional PCBs, and it can be designed with various trace widths and patterns to meet the specific electrical requirements of the application. The middle aluminum core layer, which is the key differentiator, provides a highly effective pathway for heat to be conducted away from the heat - generating components mounted on the PCB. Aluminum has a significantly higher thermal conductivity compared to traditional PCB materials like fiberglass - reinforced epoxy (FR - 4), allowing for rapid heat transfer. The bottom insulating layer serves to isolate the aluminum core from the electrical components and prevent short circuits.

One of the primary advantages of aluminum - based PCBs is their exceptional heat - dissipation capabilities. In applications such as LED lighting, power supplies, and automotive electronics, where components generate substantial amounts of heat during operation, these PCBs can effectively lower the operating temperature. By reducing the temperature, the lifespan and reliability of the electronic components are enhanced, as excessive heat can lead to component degradation, reduced performance, and even failure. For example, in high - power LED bulbs, the aluminum - based PCB helps to quickly dissipate the heat generated by the LED chips, ensuring that the LEDs operate within their optimal temperature range and maintain consistent brightness and color quality over time.

Aluminum - based PCBs also offer good mechanical strength and durability. The aluminum core provides a rigid and stable base for the PCB, making it less prone to bending or warping compared to some flexible or thin PCBs. This mechanical stability is beneficial in applications where the PCB may be subject to vibrations, shocks, or mechanical stress, such as in automotive engines or industrial machinery. Additionally, aluminum is a lightweight material, which is advantageous in applications where weight reduction is a priority, like in aerospace or portable electronic devices.

In terms of applications, aluminum - based PCBs are widely used in the LED lighting industry, from streetlights and floodlights to indoor lighting fixtures. They are also essential in power - electronic devices, including inverters, converters, and battery chargers, where efficient heat management is crucial for maintaining stable operation. In the automotive sector, these PCBs are employed in engine control units, power modules, and in - vehicle lighting systems, helping to ensure the reliable performance of electronic components in the demanding automotive environment.