-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-06-27 Views:1

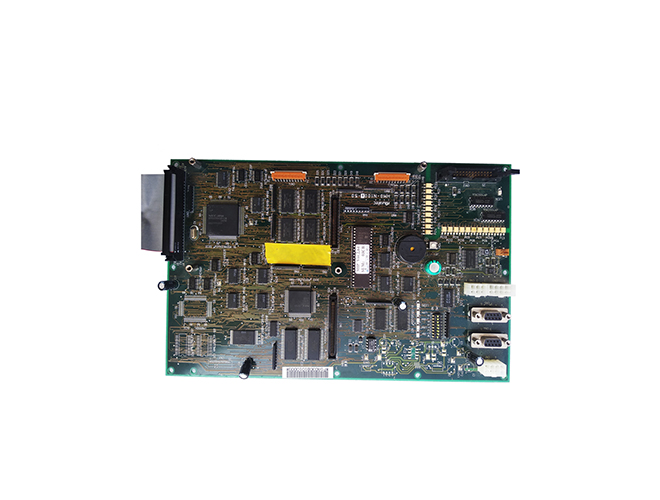

Multilayer printed circuit boards (PCBs) are indispensable components in medical imaging equipment, where they play a crucial role in ensuring the high - performance, reliability, and accuracy of these devices.

In computed tomography (CT) scanners, multilayer PCBs are used to handle the complex electrical signals generated by the detector arrays and the control systems. The high - density interconnections provided by multilayer PCBs allow for the efficient transmission of large amounts of data from the detectors, which capture X - ray attenuation information from the patient's body. These PCBs need to have excellent electrical insulation properties to prevent signal interference, as even the slightest noise can lead to image artifacts. Additionally, the thermal management capabilities of multilayer PCBs are important, as the high - power components in CT scanners, such as the X - ray tube control circuits, generate significant heat. Multilayer PCBs with built - in thermal vias and heat - dissipation layers can effectively transfer heat away from critical components, ensuring the stable operation of the scanner.

In magnetic resonance imaging (MRI) machines, multilayer PCBs are utilized in the radiofrequency (RF) coils and the gradient amplifier systems. The RF coils are responsible for transmitting and receiving RF signals to and from the patient's body to generate the MRI images. Multilayer PCBs in this application require precise impedance control to ensure the efficient transfer of RF energy. The complex routing and shielding features of multilayer PCBs help in minimizing electromagnetic interference (EMI) between different components, which is crucial for obtaining high - quality MRI images. The gradient amplifier systems, which generate the magnetic field gradients for spatial encoding of the images, also rely on multilayer PCBs to manage the high - current and high - voltage signals. The reliability of these PCBs is of utmost importance, as any failure in the MRI system can lead to inaccurate diagnoses or even pose risks to patients.

In ultrasound imaging devices, multilayer PCBs are used in the transducer arrays and the signal - processing circuits. The transducer arrays convert electrical signals into ultrasonic waves and vice versa. Multilayer PCBs with fine - pitch traces and high - density interconnections enable the precise control of the transducer elements, resulting in high - resolution ultrasound images. The signal - processing circuits, which amplify, filter, and digitize the received ultrasonic signals, also benefit from the compact and reliable design of multilayer PCBs. These PCBs need to be resistant to moisture and corrosion, as ultrasound imaging often involves the use of coupling gels and exposure to a humid environment, to ensure long - term operation of the device. Overall, the application of multilayer PCBs in medical imaging equipment is essential for advancing the capabilities of these devices and improving patient care.