-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-24 Views:1

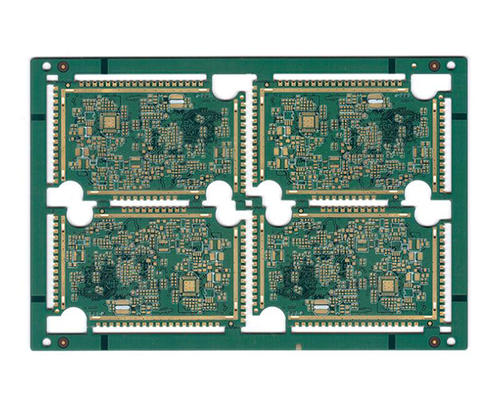

Customizable flexible PCB circuit boards offer unparalleled design flexibility and have revolutionized the electronics industry by enabling the creation of innovative and compact electronic devices. Unlike rigid PCBs, flexible PCBs are made from flexible substrate materials, such as polyimide or polyester, which allow them to be bent, folded, or twisted without damaging the electrical connections.

The key advantage of customizable flexible PCBs is their ability to conform to complex shapes and fit into tight spaces. This makes them ideal for applications where traditional rigid PCBs would be too bulky or inflexible. In wearable electronics, for example, flexible PCBs can be designed to wrap around the body or fit into the contours of a wristwatch or fitness tracker, enabling seamless integration of components such as sensors, displays, and batteries. In automotive electronics, they can be used to connect components in hard - to - reach areas, such as inside the steering wheel or along the curved surfaces of the dashboard, reducing the need for extensive wiring harnesses and saving space.

The customization of flexible PCBs allows designers to tailor the board's shape, size, and functionality according to specific application requirements. Designers can choose the number of layers, the layout of the traces, and the placement of components to optimize the performance and fit of the PCB. Additionally, flexible PCBs can be combined with rigid PCBs in rigid - flex designs, which offer the best of both worlds. Rigid - flex PCBs consist of rigid sections for mounting components and flexible sections for connecting different parts of the device, providing even more design flexibility and enabling complex 3D circuit routing.

The manufacturing process of customizable flexible PCBs involves several specialized steps. The flexible substrate is first prepared, and then the copper layers are applied using processes such as electroplating or lamination. The traces are then etched onto the copper layers, and vias are created to connect different layers if required. Surface - mount technology (SMT) is commonly used to attach components to the flexible PCB, as it provides a more reliable and compact connection. Special care is taken during the manufacturing process to ensure the durability and reliability of the flexible PCB, as the repeated bending and flexing can put stress on the electrical connections and the substrate material.

Customizable flexible PCBs are widely used in various industries, including consumer electronics, automotive, aerospace, medical, and industrial automation. In the medical field, they can be used in implantable devices or wearable medical monitors, where their flexibility and small size are crucial for patient comfort and device functionality. As technology continues to advance, the demand for customizable flexible PCB circuit boards is expected to grow, driven by the need for smaller, more flexible, and innovative electronic devices.