-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-24 Views:1

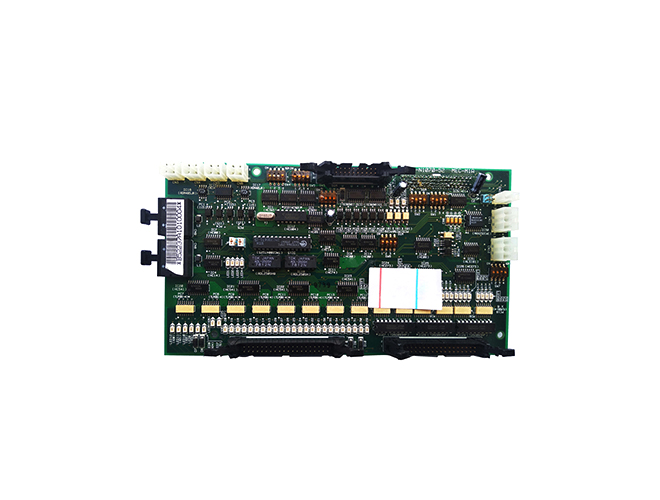

High - power PCB (Printed Circuit Board) boards are widely used in various electronic devices, such as power supplies, servers, and high - end computing systems, where a significant amount of heat is generated during operation. Effective heat dissipation is crucial to ensure the stable performance and longevity of these boards. Customized heat - dissipation solutions for high - power PCBs involve a comprehensive approach considering multiple factors.

1. Thermal Design Considerations

The first step in customized heat - dissipation for high - power PCBs is a thorough thermal design. This includes analyzing the heat - generating components on the board, such as power transistors, integrated circuits, and resistors. The power consumption and heat - generation rate of each component are calculated to determine the overall heat load of the PCB. Based on this analysis, designers can optimize the layout of components. For example, heat - generating components are often placed in areas with better ventilation or close to heat - dissipation devices. Additionally, the use of thermal vias is a common practice. Thermal vias are holes filled with a highly thermally conductive material, which can quickly transfer heat from the inner layers of the PCB to the outer layers, enhancing the overall heat - dissipation efficiency. The size, number, and distribution of thermal vias are carefully designed according to the heat - dissipation requirements of different components.

2. Heat - Dissipation Materials and Components

Selecting appropriate heat - dissipation materials and components is essential. High - thermal - conductivity materials for the PCB substrate, such as metal - core PCBs or ceramic - based PCBs, can significantly improve heat dissipation. Metal - core PCBs, for instance, have a metal layer (usually aluminum or copper) as the core, which provides excellent thermal conductivity. This allows heat to be quickly conducted away from the components. In addition to the substrate, thermal interface materials (TIMs) are used between the components and heat - sinks or other heat - dissipation devices. TIMs, such as thermal paste or thermal pads, fill the microscopic gaps between surfaces, reducing thermal resistance and improving heat transfer. Heat - sinks are also commonly used in high - power PCB designs. They come in various shapes and sizes, and their design is customized based on the available space and heat - dissipation requirements. Fins on the heat - sink increase the surface area for heat exchange with the surrounding air, enhancing the cooling effect.

3. Cooling Methods

There are several cooling methods available for high - power PCBs, and the choice depends on the specific application. Natural convection cooling relies on the natural movement of air to carry away heat. This method is suitable for low - to - medium - power applications or when space is limited. For higher - power PCBs, forced - air cooling using fans is often employed. Fans can be placed strategically on the PCB or in the enclosure to blow air over the heat - generating components and heat - sinks, increasing the rate of heat transfer. In some cases, liquid - cooling systems may be used for extremely high - power applications. Liquid - cooling involves circulating a coolant, usually a liquid with high thermal conductivity, through channels or pipes integrated with the PCB or heat - sink. This method can achieve much higher heat - dissipation efficiency compared to air - cooling, but it is more complex and costly. Customized heat - dissipation solutions often combine multiple cooling methods to achieve the best performance while considering factors such as cost, size, and reliability.