-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-12 Views:1

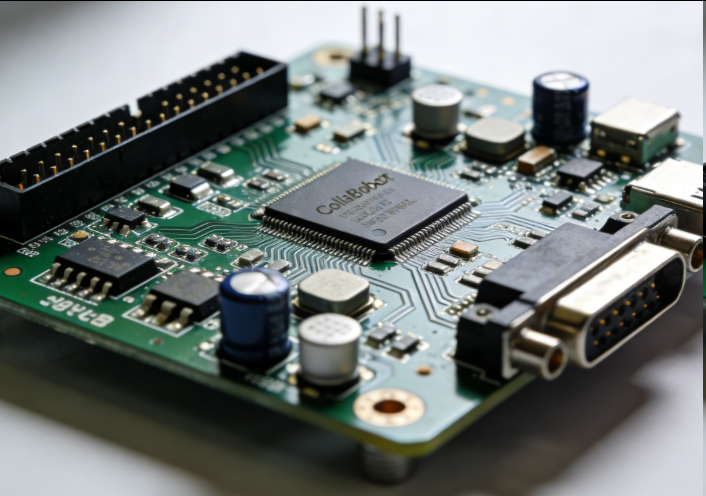

Collaborative robots, or cobots, are designed to work alongside humans in various industrial and non - industrial settings, requiring a high level of safety, precision, and flexibility. The dedicated PCB boards for collaborative robots play a pivotal role in enabling these characteristics, serving as the nerve center that controls and coordinates the robot's movements, sensors, and communication functions.

Safety is a top priority for collaborative robots, and their PCB boards are engineered with multiple safety - related features. These boards incorporate redundant circuits and fail - safe mechanisms to ensure that in the event of a component failure or unexpected malfunction, the robot can immediately enter a safe state, preventing harm to humans or damage to equipment. For example, dedicated sensor - monitoring circuits on the PCB continuously check the status of safety sensors, such as force - torque sensors and proximity sensors. If an abnormal reading is detected, the PCB quickly sends signals to the robot's control system to stop or adjust its movements. Additionally, the PCB boards are designed with isolation techniques to prevent electrical interference that could disrupt the proper functioning of safety - critical components.

Precision is another key aspect. Collaborative robots often perform tasks that require high - accuracy positioning and motion control. The PCB boards are equipped with high - performance microcontrollers and advanced signal - processing units. These components enable the precise calculation and execution of complex motion algorithms. High - resolution analog - to - digital converters (ADCs) on the PCB are used to accurately convert sensor data, such as encoder readings from the robot's joints, into digital signals for processing. The PCB also integrates high - speed communication interfaces, like SPI (Serial Peripheral Interface) and CAN (Controller Area Network), to ensure fast and reliable data transfer between different parts of the robot's control system, enabling smooth and precise movements.

Flexibility is crucial for collaborative robots, which may be used in a variety of applications. The PCB boards are designed with modular architectures, allowing for easy integration of additional components or functionality. For instance, if a new sensor or actuator needs to be added to the robot for a specific task, the modular PCB design makes it possible to connect and configure these new elements without major rewiring or redesign of the entire system. Moreover, the PCB's software - programmable features enable users to update and customize the robot's behavior and functions according to different application requirements, enhancing the robot's adaptability in diverse working environments. Overall, dedicated PCB boards for collaborative robots are carefully designed and engineered to meet the unique safety, precision, and flexibility demands of these innovative robotic systems.