-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-24 Views:1

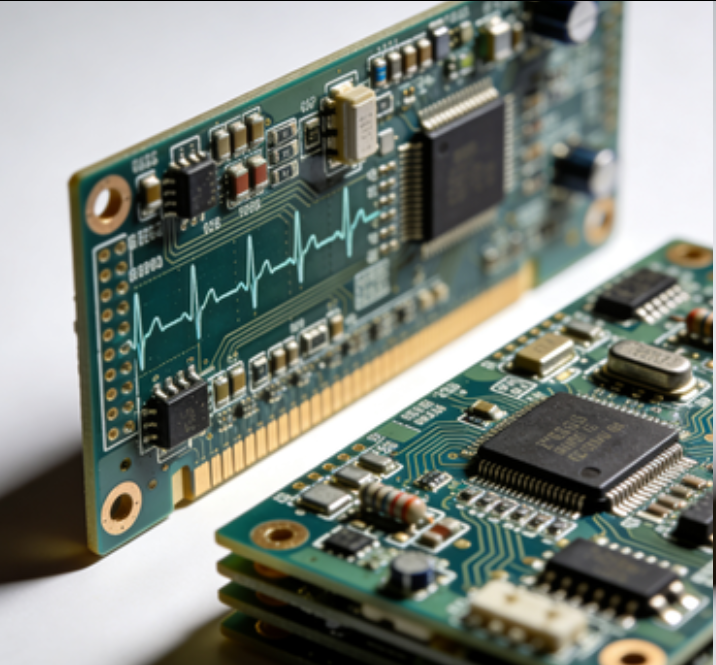

Electrocardiogram (ECG) machines are essential medical devices that record the electrical activity of the heart, providing crucial diagnostic information for healthcare professionals. To ensure accurate and reliable operation, ECG machines rely on specialized printed circuit boards (PCBs) that are meticulously designed to meet the unique requirements of cardiac signal acquisition and processing.

The design of ECG machine - specific PCBs begins with the handling of extremely weak bioelectrical signals generated by the heart. These signals typically range from a few microvolts to millivolts, making them highly susceptible to interference. The PCB must incorporate high - precision instrumentation amplifiers with extremely low noise and high common - mode rejection ratio (CMRR) to amplify these weak signals while rejecting unwanted noise. These amplifiers need to be carefully placed on the PCB, along with analog - to - digital converters (ADCs) with high resolution, to accurately capture the minute variations in the cardiac electrical signals. Additionally, proper shielding and grounding techniques are employed to minimize electromagnetic interference (EMI) from external sources, such as nearby electrical equipment or wireless signals. For example, using a dedicated ground plane and shielding enclosures around sensitive components can effectively isolate the ECG signal from interference, ensuring the integrity of the recorded data.

Material selection for ECG machine PCBs is of utmost importance due to the medical and safety requirements. The substrate materials should be biocompatible, as the PCB may be in close proximity to the patient's body during operation. Materials like FR - 4 with special coatings that are non - toxic and do not cause any adverse reactions are commonly used. Moreover, the materials should have excellent electrical insulation properties to prevent leakage currents that could pose a risk to the patient. High - quality laminates with low dielectric loss are preferred to ensure stable signal transmission, especially considering the high - frequency components present in the ECG signals.

In terms of mechanical design, the PCB for ECG machines needs to provide a robust and reliable platform for the various components. The layout should include precise mounting holes and pads for the electrodes, which are crucial for accurately detecting the cardiac signals from the patient's body. The connections between the electrodes and the signal - processing circuits on the PCB must be secure and stable to avoid any signal loss or distortion. Additionally, the PCB may be designed with specific shapes or cutouts to fit into the compact housing of the ECG machine, ensuring easy integration and maintenance.

Safety is a top priority in ECG machine PCB design. The PCB must comply with strict medical safety standards, such as those set by the International Electrotechnical Commission (IEC). This includes measures to prevent electrical shock hazards, such as proper insulation, isolation of high - voltage and low - voltage sections, and the use of safety - certified components. Regular testing and quality control procedures are carried out during the manufacturing process to ensure that the PCB meets all safety and performance requirements. Overall, a well - designed dedicated PCB board is indispensable for the accurate and safe operation of ECG machines, enabling healthcare providers to obtain reliable cardiac diagnostic information.