-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-11 Views:1

PCBA, an abbreviation for Printed Circuit Board Assembly, and PCB, which stands for Printed Circuit Board, are two integral terms in the electronics manufacturing domain. The disparities between them are evident in their manufacturing processes, physical states, and functions within electronic devices.

A PCB is essentially a bare - board structure. It is fabricated from insulating materials like fiberglass - reinforced epoxy resin (FR - 4), with conductive copper traces printed or etched onto its surface. The manufacturing process of a PCB involves several steps, starting from the design phase where the layout of the conductive pathways, holes for component insertion, and other features are planned using Computer - Aided Design (CAD) software. Then, through processes such as photolithography, etching, and drilling, the designed pattern is transferred onto the copper - clad laminate. The resulting PCB is a non - functional board that merely provides a physical framework. Its main function is to offer mechanical support for electronic components and create a platform for electrical interconnections. For example, in a simple calculator circuit, the PCB provides the base on which all the other components will be mounted.

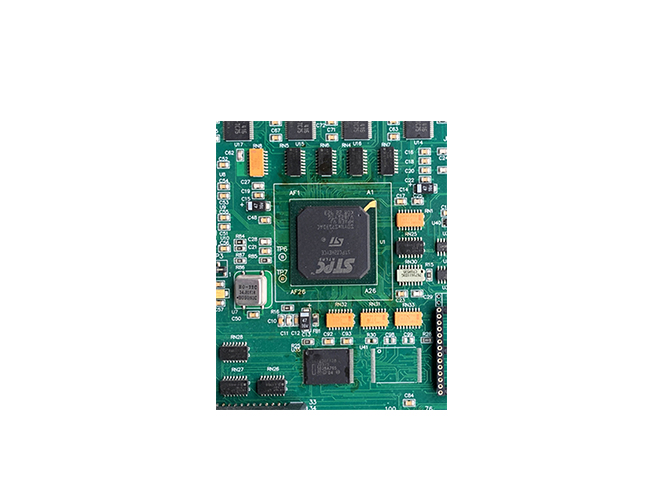

In contrast, PCBA is a fully - assembled and functional unit. After the PCB is manufactured, it undergoes the component - mounting process. This process can be either through through - hole technology (THT), where components with leads are inserted into the pre - drilled holes on the PCB and soldered on the other side, or surface - mount technology (SMT), which is more prevalent in modern electronics manufacturing. SMT involves placing tiny surface - mount components directly onto the surface of the PCB and soldering them using reflow soldering or wave soldering techniques. Components such as resistors, capacitors, integrated circuits (ICs), and transistors are soldered onto the PCB to form a PCBA. A smartphone's main circuit board is a prime example of a PCBA. It contains numerous components soldered onto the PCB, and this assembled unit is what enables the phone to perform various functions like communication, data processing, and multimedia playback. In summary, while PCB is the foundation, PCBA is the end - product ready for integration into electronic devices, adding functionality to the basic structure provided by the PCB.