-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-15 Views:1

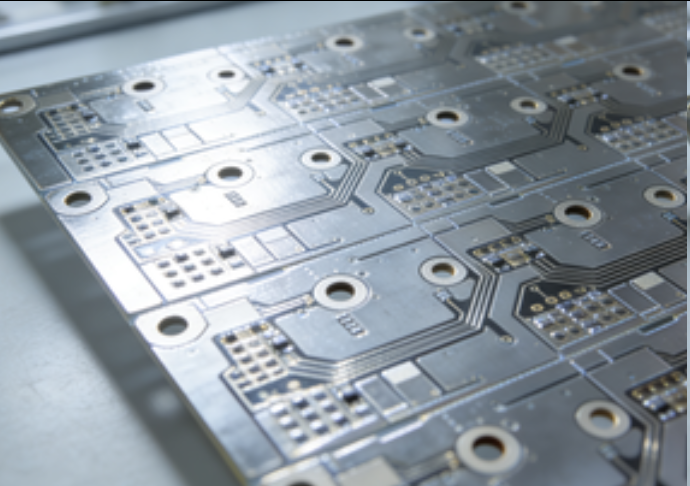

Printed Circuit Boards (PCBs) are the backbone of modern electronic devices, and ensuring their long - term reliability is of utmost importance. High - quality PCBs with anti - oxidation treatment offer enhanced durability and performance by protecting the board's copper traces and other components from the detrimental effects of oxidation.

Oxidation occurs when the copper surfaces of a PCB are exposed to air and moisture over time, leading to the formation of copper oxide layers. These oxide layers increase electrical resistance, cause signal degradation, and can ultimately lead to component failure. Anti - oxidation treatments aim to prevent or slow down this oxidation process. One of the most common anti - oxidation methods is the application of Organic Solderability Preservatives (OSP). OSP is a thin, transparent organic film that forms a protective layer on the copper surface. It chemically bonds with the copper, creating a barrier that inhibits oxygen and moisture from reaching the metal, thus preventing oxidation. This treatment is highly effective in maintaining the solderability of the PCB, ensuring that components can be soldered onto the board without issues even after long storage periods.

Another popular anti - oxidation treatment is electroless nickel immersion gold (ENIG). In this process, a thin layer of nickel is first deposited on the copper surface through an electroless plating process. This nickel layer provides corrosion resistance and serves as a base for the subsequent gold plating. The gold layer, usually just a few microns thick, is then applied by immersing the PCB in a gold - containing solution. Gold is highly resistant to oxidation and offers excellent electrical conductivity, making it ideal for protecting the PCB's surface. ENIG - treated PCBs are commonly used in high - end electronics, such as smartphones, laptops, and aerospace equipment, where reliability and performance are critical.

The quality of anti - oxidation treatment also depends on the manufacturing process. Precise control of parameters such as chemical concentrations, processing times, and temperatures during the treatment is essential to ensure a uniform and effective protective layer. Additionally, high - quality PCBs with anti - oxidation treatment often undergo rigorous quality control checks, including visual inspections, electrical tests, and environmental stress testing, to ensure that they meet the highest standards. By safeguarding the PCB from oxidation, these treatments extend the lifespan of electronic devices, reduce the risk of failures, and contribute to the overall quality and performance of modern electronics.