-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-24 Views:1

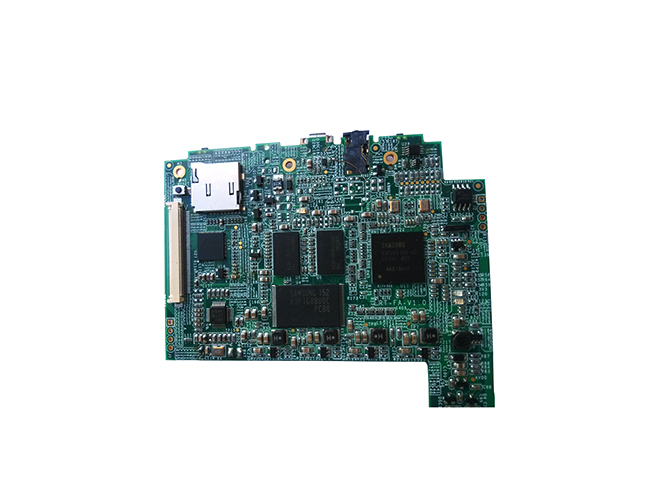

Metal - Core PCBs (MCPCBs) are a type of printed circuit board that has gained significant popularity in various industries due to their excellent thermal - management capabilities. Unlike traditional FR4 PCBs, MCPCBs feature a metal core, usually aluminum or copper, which serves as an effective heat - dissipation medium.

1. Structure and Composition

A metal - core PCB typically consists of three main layers: the metal core, an insulating layer, and a circuit layer. The metal core, usually made of aluminum or copper, provides high thermal conductivity, allowing heat to be quickly transferred away from heat - generating components. Aluminum is a popular choice due to its relatively low cost, lightweight, and good corrosion resistance. Copper, on the other hand, offers even higher thermal conductivity but is more expensive. The insulating layer, which is usually made of a thermally conductive dielectric material, separates the metal core from the circuit layer. This insulating layer has the dual function of providing electrical insulation and facilitating heat transfer from the circuit layer to the metal core. The circuit layer is similar to that of a traditional PCB, with conductive traces, pads, and vias for component attachment and electrical connections.

2. Thermal - Management Advantages

The primary advantage of metal - core PCBs is their superior thermal - management capabilities. In applications where heat generation is significant, such as in LED lighting, power electronics, and automotive electronics, MCPCBs can effectively dissipate heat, preventing components from overheating. The metal core acts as a heat sink, spreading the heat over a larger surface area and allowing it to be dissipated more efficiently into the surrounding environment. This helps to maintain the operating temperature of components within their optimal range, improving their performance, reliability, and lifespan. For example, in LED lighting applications, the use of an aluminum - core PCB can reduce the junction temperature of the LED chips, enhancing the light output and reducing the rate of LED degradation.

3. Mechanical and Electrical Properties

In addition to their thermal advantages, metal - core PCBs also offer good mechanical properties. The metal core provides mechanical strength and rigidity to the PCB, making it more resistant to bending, flexing, and mechanical stress. This is beneficial in applications where the PCB may be subjected to vibrations or physical impacts. From an electrical perspective, the insulating layer in the MCPCB ensures proper electrical insulation between the metal core and the circuit layer. The design of the circuit layer on the MCPCB follows the same principles as traditional PCBs, allowing for the integration of various electronic components. However, special considerations may be needed for high - voltage or high - frequency applications to ensure electrical safety and signal integrity.

4. Applications

Metal - core PCBs are widely used in a variety of industries. In the LED lighting industry, they are the preferred choice for heat - sinking LED chips, enabling the design of high - power, energy - efficient lighting fixtures. In power electronics, MCPCBs are used in power supplies, inverters, and motor controllers to manage the heat generated by power - semiconductor devices. In the automotive industry, they are used in engine control units, lighting systems, and other electronic components where reliable thermal management and mechanical strength are required. They are also increasingly being used in consumer electronics, such as laptops and gaming consoles, to improve the thermal performance of high - power components and enhance the overall reliability of the devices.