-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-22 Views:1

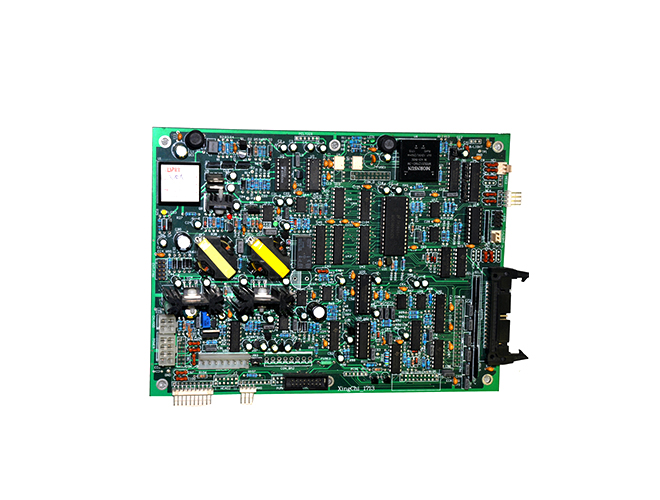

PCB board visual inspection systems are integral to the electronics manufacturing process, playing a vital role in maintaining the quality of printed circuit boards. These systems are designed to automatically detect defects on PCBs through visual means, enhancing the efficiency and accuracy of the inspection process.

A typical PCB board visual inspection system consists of high - resolution cameras, illumination sources, and advanced image - processing software. The cameras are positioned to capture clear images of the PCB surface. The illumination sources are carefully designed to provide uniform lighting, which is essential for accurate image capture. Different lighting techniques, such as front - lighting, back - lighting, and angled lighting, can be used depending on the type of defects to be detected.

The image - processing software is the heart of the visual inspection system. It analyzes the captured images to identify various types of defects. These defects can include missing or misaligned components, damaged traces, incorrect soldering, and foreign particles on the board. The software uses algorithms to compare the captured images with a reference image or a set of predefined rules. If any deviation is detected, the system flags the PCB as having a defect.

One of the key advantages of PCB board visual inspection systems is their high speed. They can quickly scan an entire PCB, allowing for high - volume production. This significantly increases the throughput of the manufacturing process. Additionally, these systems are highly accurate. They can detect even the smallest of defects, which may be overlooked by human inspectors. This helps in reducing the number of defective products reaching the market, improving the overall quality of the final electronics products.

Another advantage is their flexibility. PCB board visual inspection systems can be easily programmed to adapt to different PCB designs and manufacturing processes. They can be customized to look for specific types of defects that are more likely to occur in a particular product or production environment. The data collected during the inspection process can also be used for statistical process control, helping manufacturers to identify trends and areas for improvement in their manufacturing processes.

In conclusion, PCB board visual inspection systems are essential tools in modern electronics manufacturing. Their speed, accuracy, and flexibility make them invaluable for ensuring the quality of PCBs and ultimately, the reliability of electronic products.