-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-12 Views:1

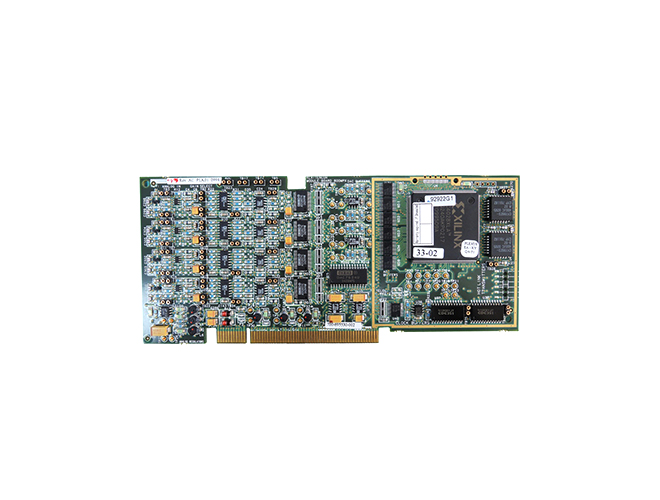

Medical device PCBA plays a crucial role in the healthcare industry, powering a wide range of equipment that is essential for diagnosis, treatment, and patient monitoring. The PCBA in medical devices must meet strict regulatory standards to ensure safety and reliability.

In diagnostic equipment such as X - ray machines, the PCBA controls the generation and detection of X - ray radiation. High - voltage power supply modules on the PCBA are responsible for providing the necessary electrical energy to produce X - rays. Image - processing components then analyze the X - ray images captured by detectors, enhancing the clarity and accuracy of the diagnosis.

Ultrasound machines also rely on PCBA. Transducer drivers on the PCBA send electrical signals to the ultrasound transducers, which convert these signals into sound waves. The received echo signals are then processed by dedicated integrated circuits on the PCBA to generate detailed images of internal organs.

Patient monitoring devices, like electrocardiogram (ECG) monitors, have PCBA that can precisely measure and record the electrical activity of the heart. Specialized analog - to - digital converters on the PCBA convert the analog signals from the electrodes attached to the patient's body into digital data that can be analyzed by the device's software. Microcontrollers on the PCBA control the overall operation of the monitor, including data storage, display, and communication with other medical systems.

In surgical equipment, such as robotic surgical arms, the PCBA is responsible for controlling the movement of the robotic components. High - precision motor drivers on the PCBA ensure smooth and accurate movement, while sensors provide feedback to the control system.

Medical device PCBA often requires the use of high - quality, reliable components due to the critical nature of the applications. These components must be able to withstand harsh environments, such as sterilization processes, and operate with a high degree of accuracy. Any malfunction in the PCBA of a medical device could have serious consequences for patient health, making strict quality control and testing an integral part of the manufacturing process.