-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-22 Views:1

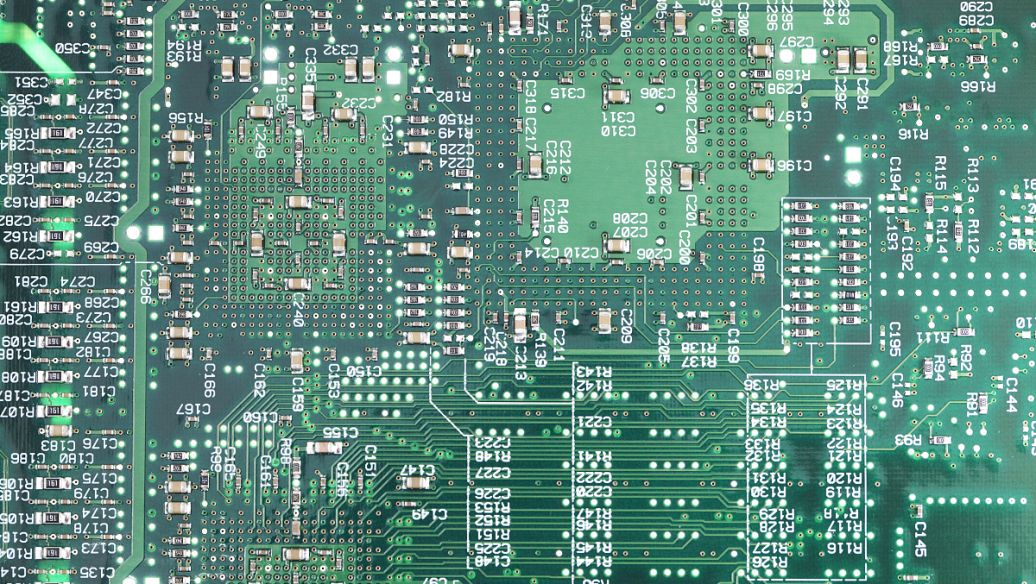

PCB (Printed Circuit Board) assembly file generation is a crucial process in the electronics manufacturing workflow. It involves creating a comprehensive set of files that provide detailed instructions for assembling a PCB, ensuring that all components are placed accurately and the board functions as intended. These files serve as a bridge between the design phase and the actual manufacturing and assembly processes.

The first step in PCB assembly file generation is the preparation of the design data. This typically starts with the PCB design software, where the circuit layout, component placement, and routing have been completed. From this design data, various types of files are extracted. The Gerber files are among the most important. They contain detailed information about the different layers of the PCB, including the copper traces, solder masks, silkscreen layers, and drill holes. These files are used by the PCB fabrication house to manufacture the bare PCB.

In addition to Gerber files, the bill of materials (BOM) is another essential component of the assembly file. The BOM lists all the components required for the PCB assembly, including their part numbers, descriptions, quantities, and manufacturers. It provides a clear inventory of what needs to be sourced and assembled onto the board. Along with the BOM, pick - and - place files are generated. These files specify the exact location and orientation of each component on the PCB. They are used by automated pick - and - place machines to accurately place the components during the assembly process.

Assembly drawings also play a significant role. These drawings provide a visual representation of the PCB assembly, showing how the components should be placed and soldered. They include important details such as component outlines, reference designators, and any special assembly instructions. Additionally, test files may be generated, which are used for quality control purposes. These files can include information for in - circuit testing (ICT) or functional testing to ensure that the assembled PCB meets the required specifications.

Accurate PCB assembly file generation is vital for several reasons. It ensures that the PCB fabrication and assembly processes can proceed smoothly without errors or misunderstandings. A well - prepared set of files reduces the risk of component placement mistakes, incorrect soldering, and other assembly - related issues. Moreover, it helps in streamlining the supply chain by providing clear information to component suppliers and manufacturers. In today's competitive electronics market, where time - to - market is crucial, efficient and error - free PCB assembly file generation can significantly impact the overall success of a product development project.