-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-18 Views:1

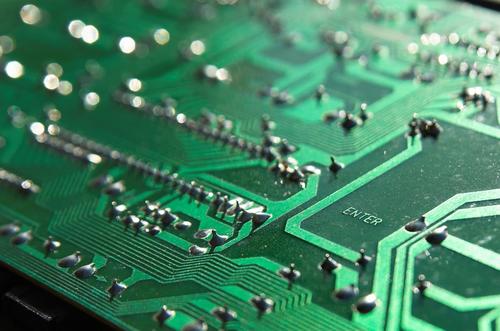

Printed Circuit Boards (PCBs) adapted to encoding circuits are fundamental in converting various forms of information into a standardized code format, which is crucial for data transmission, storage, and processing in modern electronic systems. These specialized PCBs are designed to integrate key components and establish precise electrical pathways that enable efficient encoding operations, ensuring the integrity and accuracy of the encoded data.

The design of PCB boards for encoding circuits commences with the strategic placement of essential components. Encoding circuits typically incorporate elements such as encoders, multiplexers, logic gates, and memory chips. For example, in a digital - to - analog encoding circuit, an encoder IC is the core component responsible for transforming digital signals into analog - compatible codes. The PCB layout must ensure that the input digital signal lines are routed accurately to the encoder's input pins, minimizing signal interference and distortion. The output lines from the encoder, carrying the encoded data, should also be carefully connected to the subsequent circuits, with proper impedance matching to prevent signal reflections.

Signal integrity is of utmost importance in encoding - circuit PCBs. As encoding often deals with high - speed digital signals, any degradation in signal quality can lead to errors in the encoded data. To address this, differential signaling techniques are frequently employed for critical signal lines. This approach reduces electromagnetic interference and improves the 抗干扰能力 of the circuit, ensuring that the encoding process remains accurate. Additionally, proper trace routing, including avoiding sharp bends and keeping traces as short as possible, helps maintain signal integrity by minimizing signal delay and crosstalk between different lines. Shielding may also be necessary for high - frequency encoding circuits, especially those operating in noisy electromagnetic environments, to protect the sensitive components from external interference.

Power - supply design is another critical aspect of encoding - circuit PCBs. A stable and clean power supply is essential for the accurate operation of the encoding components. Decoupling capacitors should be placed close to the power pins of the ICs to filter out high - frequency noise from the power supply. In more complex encoding systems, multiple power - supply rails may be required to power different functional blocks, such as analog and digital sections. The power - distribution network on the PCB must be carefully designed to ensure proper voltage regulation and isolation between these rails, preventing electrical noise from affecting the encoding performance.

Testing and verification are indispensable steps in the development of PCB boards for encoding circuits. Logic analyzers and data - analysis tools are used to input test data into the encoding circuit and analyze the output encoded data. By comparing the encoded results with the expected output, engineers can identify and correct any errors in the encoding process. Adjustments to the component values, PCB layout, and power - supply settings may be necessary to optimize the performance of the encoding circuit. Through meticulous design, component selection, and testing, PCB boards adapted to encoding circuits can accurately convert information into the desired code format, facilitating seamless data handling in a wide range of electronic applications.