-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-05 Views:1

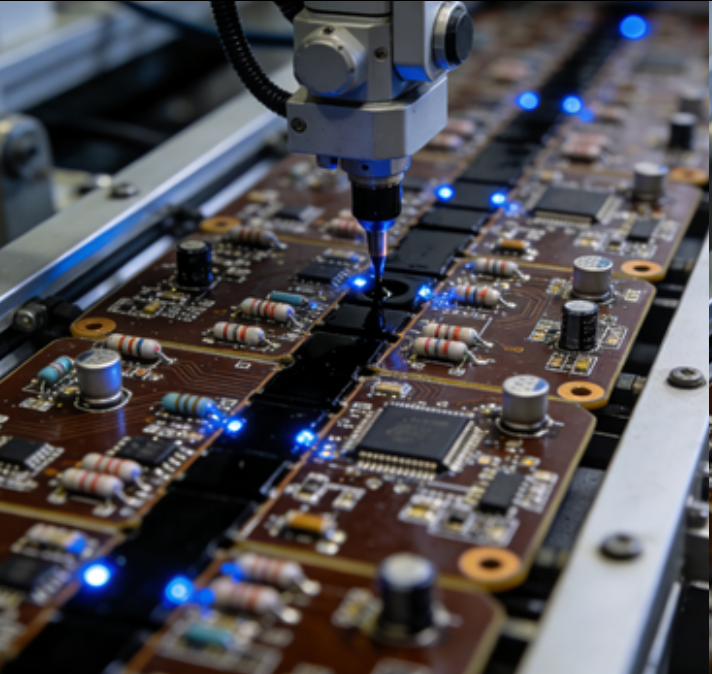

Spray painting robots are extensively utilized in industries like automotive manufacturing, furniture production, and metal finishing, where consistent and high - quality coating is essential. The PCB boards compatible with spray painting robots are meticulously engineered to meet the unique demands of these applications, which involve exposure to paint particles, solvents, and varying environmental conditions, while ensuring precise control over the spraying process.

One of the primary challenges for PCB boards in spray painting robots is protection against paint particles and solvents. These substances can infiltrate the electronic components of the PCB, causing short circuits, corrosion, and ultimately, component failure. To address this, the PCB boards are coated with specialized, chemical - resistant conformal coatings. These coatings form a thin, protective layer over the entire surface of the PCB, sealing off the components from the surrounding environment. Additionally, the boards are often housed in sealed enclosures with gaskets to further prevent the ingress of paint and solvents. Some advanced designs even incorporate air - filtering systems within the enclosures to maintain a clean and safe internal environment for the PCB.

Precision control is crucial for spray painting robots to achieve uniform paint application. The PCB boards integrate high - accuracy control circuits that manage the movement of the robot's joints, the flow rate of the paint, and the spray pattern. High - performance microcontrollers on the PCB execute complex algorithms to precisely position the spray gun, adjust the spray angle, and control the paint flow based on the shape and size of the object being painted. For example, when painting a car body, the PCB - controlled system can adjust the spray parameters in real - time to ensure that the paint is evenly distributed across different surfaces, including curves and corners. The boards also interface with sensors such as flow sensors for paint volume monitoring and pressure sensors for maintaining the correct spray pressure, enabling continuous feedback and adjustment of the spraying process.

Communication is another vital aspect. Spray painting robots often need to integrate with other equipment on the production line, such as conveyor systems and quality - inspection devices. The PCB boards are equipped with a variety of communication interfaces, including Ethernet, Profibus, and DeviceNet. These interfaces allow the spray painting robot to receive production schedules, coordinate its operations with other machinery, and send data related to the spraying process, such as paint consumption and coating thickness, to a central control system. In a large - scale automotive factory, for instance, multiple spray painting robots can communicate via their PCB - enabled interfaces to ensure a seamless and efficient painting process across the entire production line. Overall, PCB boards compatible with spray painting robots are designed to provide reliable operation, precise control, and effective integration, enabling these robots to deliver high - quality paint finishes in industrial applications.