-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-18 Views:1

Crystal oscillator components are indispensable in Printed Circuit Boards (PCBs), serving as the heartbeat that provides a stable and precise clock signal for the proper functioning of electronic circuits. These components are based on the piezoelectric effect of quartz crystals, which means that when an electric field is applied to the crystal, it vibrates at a specific frequency, and conversely, mechanical stress on the crystal generates an electric signal.

In a PCB, crystal oscillators are primarily used to synchronize the operations of various integrated circuits (ICs), microcontrollers, and other digital components. For example, in a microprocessor - based system on a PCB, the crystal oscillator sets the clock speed, determining how quickly the microprocessor can execute instructions. A stable and accurate clock signal is crucial as it ensures that all components in the circuit work in harmony, preventing data corruption and system malfunctions. Without a reliable crystal oscillator, digital circuits would lack the timing reference needed for proper data processing, communication, and overall operation.

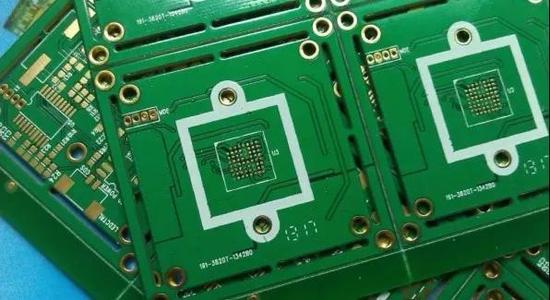

There are different types of crystal oscillator components commonly used in PCBs. The most basic type is the through - hole crystal oscillator, which has leads that are inserted into holes on the PCB and soldered in place. This type is suitable for prototyping and some lower - density PCB designs. Surface - mount technology (SMT) crystal oscillators have become increasingly popular due to their smaller size and compatibility with automated PCB assembly processes. SMT crystal oscillators are directly soldered onto the surface of the PCB, saving space and enabling more compact circuit designs, which are essential in modern consumer electronics like smartphones, tablets, and wearable devices.

The performance of crystal oscillator components is characterized by several key parameters. Frequency stability is one of the most critical, as it determines how consistent the oscillator's output frequency remains over time, temperature variations, and other environmental factors. High - quality crystal oscillators can maintain extremely stable frequencies, with variations often measured in parts per million (ppm). The load capacitance of the crystal oscillator also affects its performance, and it must be carefully matched with the circuit design to ensure accurate frequency generation. Additionally, the drive level, which is the amount of electrical power supplied to the crystal, needs to be optimized to avoid over - driving the crystal, which could lead to frequency instability or even damage to the component.

Crystal oscillator components find applications in a wide range of PCB - based systems. In communication devices such as routers, modems, and wireless access points, they provide the necessary clock signals for data transmission and reception, ensuring accurate modulation and demodulation of signals. In computer motherboards, crystal oscillators are used to set the system clock, which controls the operation of the CPU, memory, and other components. They are also essential in industrial control systems, where precise timing is required for processes such as motor control, data acquisition, and process automation. crystal oscillator components are fundamental to the reliable operation of PCBs, and their proper selection and integration are vital for the success of any electronic design.