-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-22 Views:1

PCB LED beads have become a cornerstone in modern electronic devices, offering a versatile and efficient lighting solution with a wide range of applications. These light - emitting diodes (LEDs) are specifically designed for integration onto printed circuit boards, providing designers with the flexibility to create customized lighting systems.

The structure of PCB LED beads typically consists of a semiconductor chip encased in a protective epoxy or silicone housing, which also serves to focus and direct the emitted light. The semiconductor material, often made from compounds like gallium arsenide or gallium nitride, is responsible for the light - emitting process. When an electric current passes through the chip, electrons recombine with electron holes, releasing energy in the form of photons, thus producing light. One of the key advantages of LED beads on PCBs is their energy - efficiency. Compared to traditional incandescent bulbs, LED beads consume significantly less power while producing the same or even more luminous output, making them ideal for battery - powered devices such as smartphones, tablets, and wearable electronics.

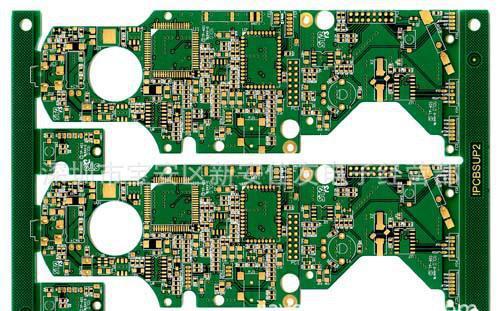

In PCB design, the placement and soldering of LED beads require careful consideration. Surface - mount technology (SMT) is commonly used for attaching LED beads to PCBs due to its precision and ability to handle small - sized components. The solder pads on the PCB must be designed to match the dimensions of the LED bead's leads, ensuring a secure and reliable electrical connection. Additionally, thermal management is crucial for LED beads, as excessive heat can reduce their lifespan and performance. Designers often incorporate heat - dissipating elements, such as thermal vias or copper planes, into the PCB layout to efficiently transfer heat away from the LEDs.

The applications of PCB LED beads are diverse. In consumer electronics, they are used for indicator lights, backlighting in displays, and decorative lighting. In automotive electronics, LED beads are employed in headlights, taillights, and interior lighting systems, providing better visibility and energy savings. In the field of lighting fixtures, LED - based PCB modules are revolutionizing the industry, offering long - lasting, customizable, and environmentally friendly lighting solutions. As technology continues to advance, PCB LED beads are expected to become even more efficient, compact, and versatile, further expanding their use in various electronic and lighting applications.