-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-27 Views:1

PCB Mechanical Testing is a set of standardized evaluations designed to assess a printed circuit board’s ability to withstand physical stress, deformation, and environmental wear—critical for ensuring reliability in applications where PCBs face mechanical forces (e.g., vibration in automotive, bending in wearables, or shock in industrial equipment). Unlike electrical testing (which focuses on signal integrity), mechanical testing validates the PCB’s structural integrity and material performance, preventing premature failure due to physical damage.

Key mechanical tests include bend testing: applying controlled force to flex the PCB (relevant for flex PCBs or rigid PCBs in devices with minor movement) to measure its bending strength and resistance to trace cracking. For example, a flex PCB used in a foldable phone undergoes 10,000+ bend cycles (at a specified radius) to ensure traces remain intact. Tensile testing evaluates the strength of copper traces and substrate bonds—pulling samples to measure the force required to separate layers or break traces, ensuring durability during assembly (e.g., soldering or component mounting).

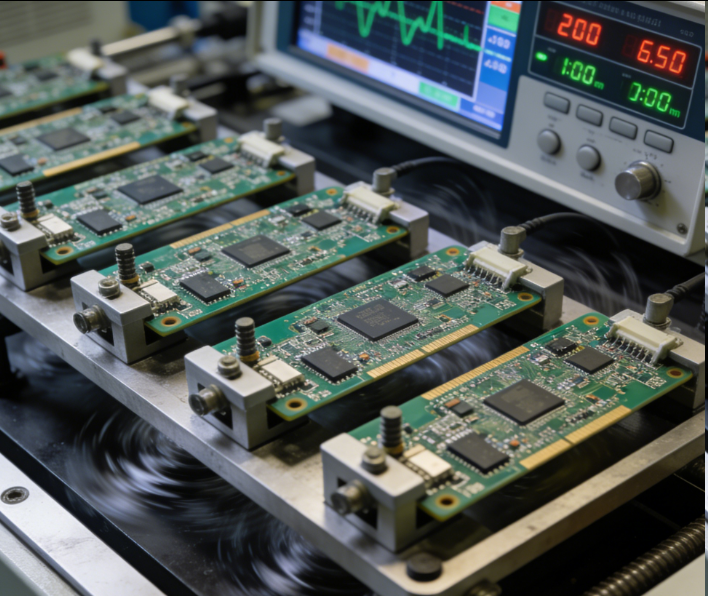

Vibration testing simulates real-world conditions (e.g., automotive engine vibration or industrial machinery oscillation) using shaker tables, subjecting PCBs to controlled frequency and amplitude vibrations to detect loose components, trace delamination, or solder joint failure. Shock testing applies sudden impact forces (e.g., drops or collisions) to assess the PCB’s ability to withstand acute stress—critical for portable devices like smartphones or medical monitors.

Additional tests include thermal shock testing (cycling between extreme temperatures to check for substrate warping or trace cracking) and solderability testing (ensuring component pads maintain good solder adhesion after thermal stress). All mechanical tests follow industry standards (e.g., IPC-TM-650 for PCB testing methods) to ensure consistency. For manufacturers, mechanical testing identifies weak points in PCB design (e.g., thin traces prone to breaking) or material selection, ensuring the final product can withstand the physical demands of its intended use.