-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-29 Views:1

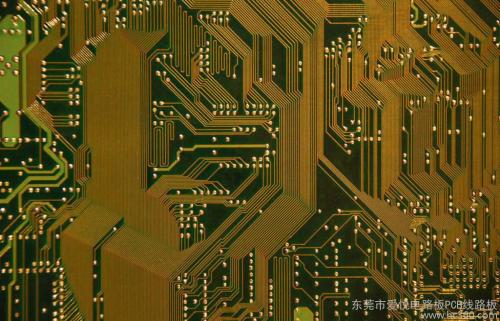

PCB thermal design focuses on managing heat generation and dissipation within a printed circuit board to ensure components operate within their safe temperature ranges, preventing performance degradation, reliability issues, or premature failure. Electronic components—especially high-power devices like microprocessors, power transistors, and voltage regulators—generate significant heat during operation, which can raise PCB temperatures beyond acceptable limits (typically 85°C for commercial components, 125°C for industrial grades). Effective thermal design ensures heat is efficiently transferred away from hot components to the environment, maintaining optimal operating conditions.

Key strategies include thermal conduction paths. Using thick copper traces (2–4 oz) for power and ground planes increases thermal conductivity, allowing heat to spread across the PCB. Thermal vias—plated through-holes filled with solder or thermal epoxy—connect hot components (e.g., a power IC) to internal or bottom copper layers, distributing heat away from the source. For example, a BGA (Ball Grid Array) chip might use an array of thermal vias beneath its package to transfer heat to a large ground plane, acting as a heat spreader.

Component placement is critical for thermal management. High-power devices should be positioned away from heat-sensitive components (e.g., sensors, electrolytic capacitors) and placed near PCB edges or heat sinks to facilitate heat dissipation. Spacing between hot components prevents thermal crowding, allowing air to circulate. In addition, orienting components to align with airflow (in forced-cooling systems) maximizes convective heat transfer.

Heat sinks and cooling devices are integrated for high-power applications. Passive heat sinks—aluminum or copper fins attached to components via thermal adhesive or clips—increase surface area for natural convection. For higher heat loads, active cooling solutions like fans, heat pipes, or Peltier devices are used. Heat pipes, for instance, transfer heat from a hot component to a remote heat sink via phase change (liquid to vapor), enabling efficient cooling in space-constrained designs.

Thermal simulation tools like Flotherm or ANSYS Icepak are used to model heat flow, predict hotspots, and optimize designs before prototyping. These tools simulate temperature distributions based on component power dissipation, PCB material properties (e.g., FR-4 thermal conductivity ~0.3 W/m·K), and cooling methods, allowing engineers to adjust trace widths, via placement, or heat sink size.

By integrating these thermal design practices, PCBs can handle power densities up to 100+ W/cm² (in advanced applications like 5G base stations or electric vehicle controllers), ensuring long-term reliability and performance. Thermal design is particularly critical in compact devices where space constraints limit cooling options, making efficient heat management a key factor in product success.