-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-10-10 Views:1

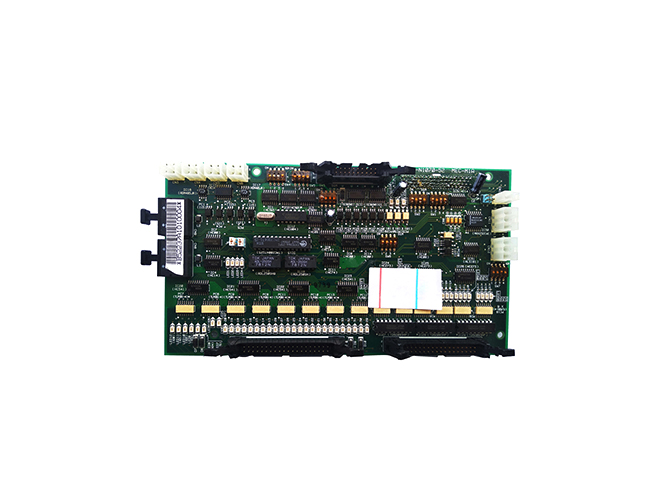

Printed Circuit Boards (PCBs) with precise impedance control are crucial in modern high - speed electronic systems. Impedance, in the context of PCBs, refers to the opposition that a circuit presents to the passage of an alternating current at a given frequency. Precise impedance control ensures that electrical signals can travel along the PCB traces without significant reflections, crosstalk, or signal degradation, which is essential for high - speed data transmission and the reliable operation of advanced electronic devices.

The impedance of a PCB trace is determined by several factors, including the trace width, trace thickness, the distance between traces, the dielectric constant of the substrate material, and the height of the dielectric layer. To achieve precise impedance control, manufacturers use specialized design software that can accurately calculate and simulate the impedance based on these parameters. For example, in high - speed digital circuits such as those found in servers, graphics cards, and high - end networking equipment, the impedance of the traces must be tightly controlled, often within a tolerance of ±5 ohms.

During the manufacturing process, strict quality control measures are implemented to ensure that the actual impedance of the PCB traces matches the design specifications. This involves using high - precision manufacturing equipment for trace etching, which can maintain consistent trace widths and depths. The choice of substrate material is also critical. Materials with a stable and well - defined dielectric constant, such as Rogers RT/duroid series or Isola FR408HR, are commonly used in high - impedance - controlled PCBs. These materials offer low loss and excellent electrical performance over a wide range of frequencies.

In addition, impedance - controlled PCBs often require special termination techniques. Proper termination helps to absorb the electrical signals at the end of the traces, preventing reflections that can distort the signals. Techniques such as series termination, parallel termination, and AC termination are used depending on the specific requirements of the circuit.

Testing impedance - controlled PCBs is a complex process that involves using specialized test equipment, such as time - domain reflectometers (TDRs) and vector network analyzers (VNAs). These instruments can measure the impedance of the PCB traces accurately and detect any impedance mismatches or discontinuities. By ensuring precise impedance control, PCB designers and manufacturers can create reliable and high - performance electronic products that meet the demanding requirements of modern communication and computing technologies.