-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-11 Views:1

PCBA Automated Optical Inspection (AOI) is an advanced non-contact testing technology designed to detect defects in Printed Circuit Board Assemblies (PCBAs) during the electronics manufacturing process. Unlike manual visual inspection (MVI), which relies on human eyes and is prone to error, AOI uses high-resolution cameras, specialized lighting systems, and machine vision algorithms to automatically scan, analyze, and identify flaws in PCBAs—such as missing components, soldering defects, component misalignment, and incorrect part placements. This makes it an indispensable tool in high-volume electronics manufacturing industries like consumer electronics, automotive electronics, medical devices, and aerospace, where precision and defect-free production are critical to product performance and safety.

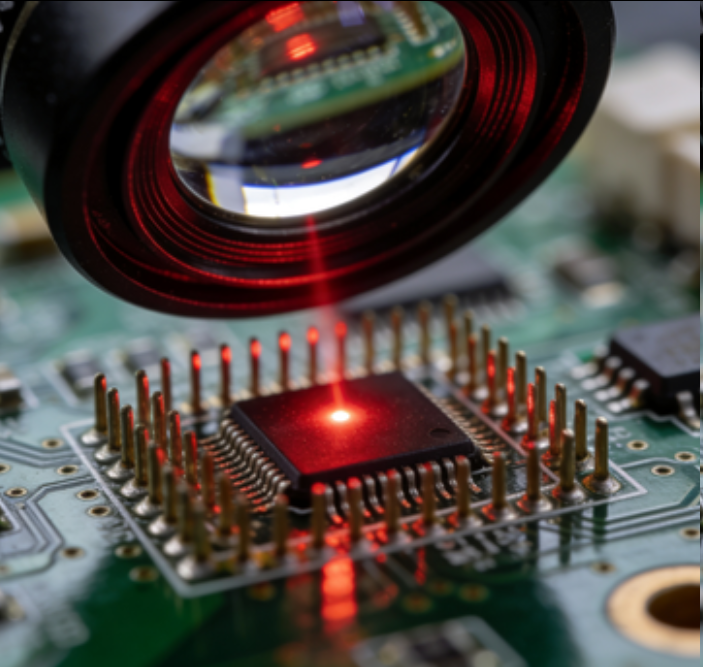

The core workflow of PCBA AOI involves four key stages: image acquisition, image processing, defect detection, and reporting. First, the PCBA is placed on a conveyor belt and transported under high-resolution cameras (typically 5–20 megapixels) equipped with multi-angle lighting (e.g., top, side, and coaxial lighting). The lighting is tailored to highlight specific features—for example, side lighting emphasizes component height, while coaxial lighting detects surface defects like solder bridges. Second, the cameras capture high-contrast images of the PCBA, which are then processed by machine vision software. The software uses pattern matching, edge detection, and pixel intensity analysis to compare the captured images with a “golden sample” (a defect-free PCBA template) or predefined design rules (e.g., component dimensions, solder joint shape). Third, any deviations from the template or rules are flagged as potential defects—common flaws include tombstoning (components standing on one end), cold solder joints (dull, irregular solder), and missing resistors/capacitors. Finally, the system generates a detailed report with defect locations, types, and severity levels, allowing technicians to review and address issues quickly.

Key advantages of PCBA AOI include high accuracy, speed, and consistency. AOI systems can detect defects as small as 0.1mm (e.g., tiny solder balls) with an accuracy rate of over 99%, far exceeding manual inspection (which typically has an accuracy rate of 85–90%). They operate at high speeds, inspecting up to 60 PCBAs per minute for small boards, making them suitable for mass production lines. Unlike human inspectors, AOI systems do not suffer from fatigue or subjectivity, ensuring consistent defect detection across every PCBA. Additionally, modern AOI systems integrate with Manufacturing Execution Systems (MES), enabling real-time data sharing and process optimization—for example, if the system detects a spike in solder defects, it can trigger an alert to adjust the reflow oven temperature.

Practical applications of PCBA AOI span the entire PCBA manufacturing process, from post-placement (after components are mounted) to post-reflow (after soldering). In post-placement inspection, AOI verifies that components are correctly placed and oriented (e.g., diodes with the correct polarity) before soldering, preventing costly rework. In post-reflow inspection, it checks solder joint quality, ensuring that joints are strong, void-free, and properly shaped. In automotive electronics, AOI inspects PCBAs for safety-critical components (e.g., airbag control modules), where even a small defect could lead to catastrophic failures. In medical devices (e.g., pacemakers), it ensures that PCBAs meet strict regulatory standards (e.g., FDA requirements) for reliability. While PCBA AOI systems require initial setup and programming (to create golden samples and rules), their ability to reduce defects, lower rework costs, and improve production efficiency makes them a cornerstone of modern electronics manufacturing. For any PCBA production line seeking to enhance quality control, AOI is an essential investment.