-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-04 Views:1

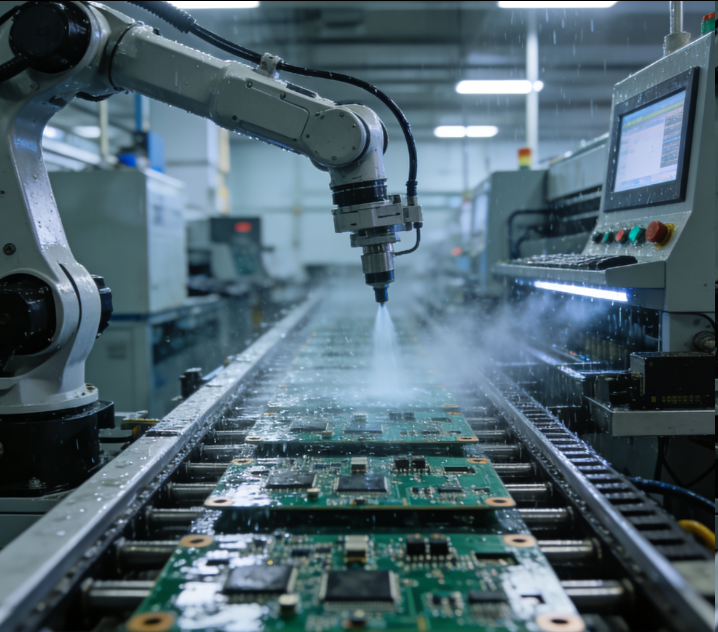

PCBA waterproofing treatment is a critical process designed to shield printed circuit board assemblies from the detrimental effects of moisture, liquids, and humid environments. This treatment is indispensable for PCBs used in outdoor equipment, marine devices, medical instruments, and industrial control systems where exposure to water or condensation is inevitable. The core objective is to create a barrier that prevents water molecules from penetrating the PCB surface, avoiding short circuits, corrosion of metal components, and degradation of electronic performance.

Common waterproofing techniques include the application of waterproof coatings, potting compounds, and the use of waterproof enclosures. Waterproof coatings, such as polyurethane and silicone-based materials, form a flexible and durable film that adheres tightly to the PCB and its components. Potting, on the other hand, involves encapsulating the entire PCBA in a resinous material, providing comprehensive protection against not only water but also mechanical shocks and chemical erosion. The selection of the appropriate method depends on factors like the operating environment, temperature range, and the size of the PCBA.

Effective waterproofing treatment requires strict quality control throughout the process. Prior to treatment, the PCBA must be thoroughly cleaned to remove contaminants like flux residues and dust, which can compromise the adhesion of waterproof materials. After application, tests such as the IPX7 or IPX8 immersion test are conducted to verify the waterproof performance, ensuring the PCBA can operate reliably in harsh, wet conditions for an extended period.