-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-05-13 Views:1

Printed Circuit Board Assembly (PCBA) for industrial control applications is designed to meet the demanding requirements of industrial environments, where reliability, durability, and precise control are of utmost importance. Industrial control systems are used in a wide range of sectors, including manufacturing, energy, and automation, and PCBA plays a central role in ensuring their smooth operation.

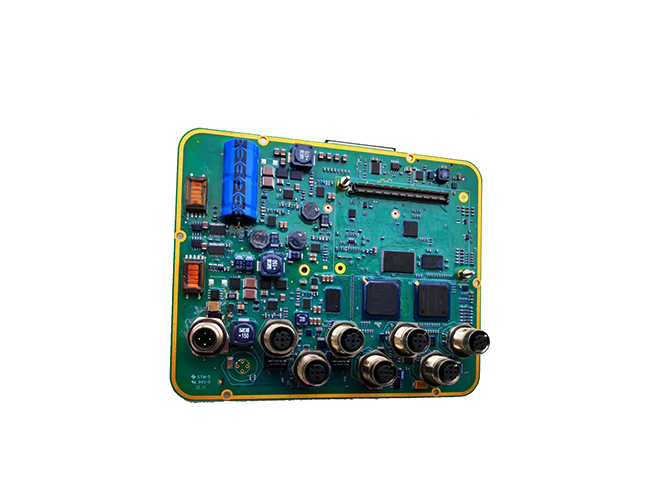

In industrial control, PCBA is used to build control panels, programmable logic controllers (PLCs), motor drives, and other critical components. These PCBA designs are engineered to withstand harsh conditions such as high temperatures, humidity, dust, and vibration. To achieve this, high - quality components and materials are selected. Components with a wide operating temperature range, high - reliability ratings, and resistance to environmental factors are preferred. For example, industrial - grade integrated circuits, capacitors, and resistors are used to ensure stable performance over long periods.

The layout and design of PCBA for industrial control also focus on electromagnetic compatibility (EMC). Industrial environments are often filled with various sources of electromagnetic interference (EMI), such as motors, generators, and power lines. PCBA designs incorporate shielding techniques, proper grounding, and careful component placement to minimize EMI and ensure that the control system operates without interference. This is crucial for maintaining the accuracy of control signals and preventing malfunctions that could lead to production downtime or safety hazards.

Another key aspect of PCBA for industrial control is modularity. Industrial control systems often need to be flexible and easily expandable. PCBA designs are therefore made modular, allowing for the addition or replacement of components as needed. This modular approach simplifies maintenance and upgrades, reducing the time and cost associated with system modifications. For example, in a large - scale manufacturing plant, if a particular control function needs to be enhanced, a new module can be easily integrated into the existing PCBA without having to re - design the entire system.

Furthermore, PCBA for industrial control typically includes advanced communication interfaces. These interfaces, such as Ethernet, Profibus, or Modbus, enable seamless communication between different components of the industrial control system and with external devices. The PCBA is designed to support reliable data transmission, ensuring that control commands and feedback information are accurately and promptly exchanged. Overall, PCBA for industrial control is a specialized and highly engineered solution that provides the foundation for reliable, efficient, and adaptable industrial control systems.