-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-07 Views:1

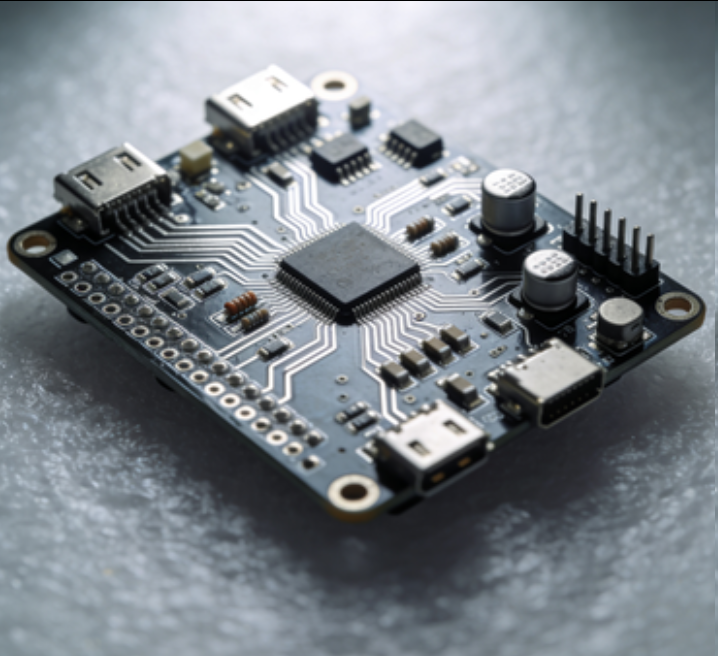

Printed Circuit Boards (PCBs) adapted for smart home applications are the key enablers behind the seamless operation and connectivity of various intelligent devices within modern households. These PCBs are engineered to meet the unique requirements of smart home systems, which demand a combination of functionality, energy efficiency, reliability, and compatibility with diverse communication protocols.

One of the primary characteristics of smart home - adapted PCBs is their support for multiple wireless communication standards. Smart home devices often rely on technologies such as Wi - Fi, Bluetooth, ZigBee, Z - Wave, and Thread to communicate with each other and with the central control hub. PCBs designed for this purpose incorporate antennas and radio frequency (RF) circuits that can operate across these different frequency bands, ensuring seamless connectivity. For example, a PCB in a smart thermostat may need to connect to a home Wi - Fi network for remote control via a mobile app and also use ZigBee to communicate with other smart sensors and actuators in the house. To achieve this multi - standard support, advanced multi - band antenna designs and integrated RF modules are employed, allowing the PCB to handle multiple wireless signals simultaneously without interference.

Energy efficiency is another crucial aspect of PCBs for smart home applications. Many smart home devices, such as smart sensors and battery - powered cameras, operate on limited power sources. PCBs in these devices are designed with low - power components and optimized power management circuits. Microcontrollers with low - power consumption modes are commonly used, and power - saving techniques like dynamic voltage scaling and sleep modes are implemented. Additionally, the PCB layout is carefully designed to minimize power losses due to resistance in traces and components. For instance, shorter and wider traces are used for power - carrying paths to reduce voltage drops, and power - hungry components are placed close to the power source to minimize power loss during transmission.

Reliability is of utmost importance in smart home PCBs, as any failure could disrupt the functionality of the entire smart home system. These PCBs are built to withstand the normal environmental conditions of a household, including temperature variations, humidity, and dust. They are often constructed using high - quality materials, such as FR - 4 laminates with good electrical insulation properties and resistance to moisture. Surface mount technology (SMT) is widely used for component assembly, providing a more robust and reliable connection compared to through - hole technology. Furthermore, PCBs for smart home applications undergo rigorous testing, including functional testing, electrical testing, and environmental testing, to ensure they can operate reliably over an extended period.

Compatibility and integration are also key considerations. Smart home systems consist of a wide range of devices from different manufacturers, and the PCBs need to be compatible with various software platforms and communication protocols. Standardized interfaces and communication protocols are adhered to, enabling easy integration of new devices into the existing smart home ecosystem. For example, PCBs in smart home devices may support the Matter standard, which aims to provide a unified and interoperable communication framework for smart home products. With the continuous growth of the smart home market, the demand for high - performance, energy - efficient, and reliable PCBs will continue to rise, driving further innovation in PCB design and manufacturing for this application.