-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-05-13 Views:1

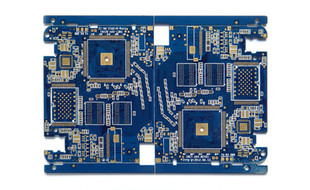

Printed Circuit Boards (PCBs) play an indispensable role in LED lighting systems, serving as the foundation for efficient electrical connectivity, thermal management, and overall performance optimization. In LED lighting applications, PCBs are designed with specific characteristics to meet the unique requirements of light - emitting diodes.

One of the primary functions of PCBs in LED lighting is to provide a reliable electrical connection for the LEDs. LEDs are semiconductor devices that require a precise and stable electrical supply to operate efficiently. PCBs for LED lighting are typically designed with carefully routed traces to distribute the electrical current evenly among the LEDs. The layout of the traces is crucial, as it can affect the uniformity of the light output. By ensuring that each LED receives the appropriate amount of current, the PCB helps to prevent issues such as premature failure of individual LEDs or uneven brightness across the lighting fixture.

Thermal management is another critical aspect of PCBs for LED lighting. LEDs generate heat during operation, and if this heat is not dissipated effectively, it can lead to a decrease in light output, color shift, and reduced lifespan. To address this, LED PCBs are often made from materials with high thermal conductivity, such as metal - core PCBs (MCPCBs). MCPCBs typically have a metal substrate, usually aluminum or copper, which acts as an efficient heat sink. The metal substrate allows heat to be quickly transferred away from the LEDs, keeping their operating temperature within an optimal range. Additionally, the PCB design may incorporate heat - spreading patterns or vias to further enhance thermal dissipation.

The design of PCBs for LED lighting also takes into account optical considerations. The arrangement of the LEDs on the PCB can impact the light distribution and the overall lighting effect. For example, in some applications, such as downlights or spotlights, the LEDs may be arranged in a specific pattern to achieve a focused beam of light. In other cases, like panel lights or linear fixtures, a more uniform distribution of LEDs is required to produce even illumination. PCBs can be customized with different shapes and sizes to fit the specific form factor of the lighting fixture, enabling seamless integration of the LED components.

Moreover, PCBs for LED lighting often include additional features such as dimming control circuits. Dimming functionality allows users to adjust the brightness of the LED lights according to their needs, which is not only energy - efficient but also provides flexibility in creating different lighting atmospheres. The PCB may incorporate electronic components, such as integrated circuits or resistors, to implement dimming control methods like pulse - width modulation (PWM) or analog dimming. Overall, PCBs are essential components in LED lighting systems, enabling reliable operation, effective thermal management, and optimized optical performance.