-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-06 Views:1

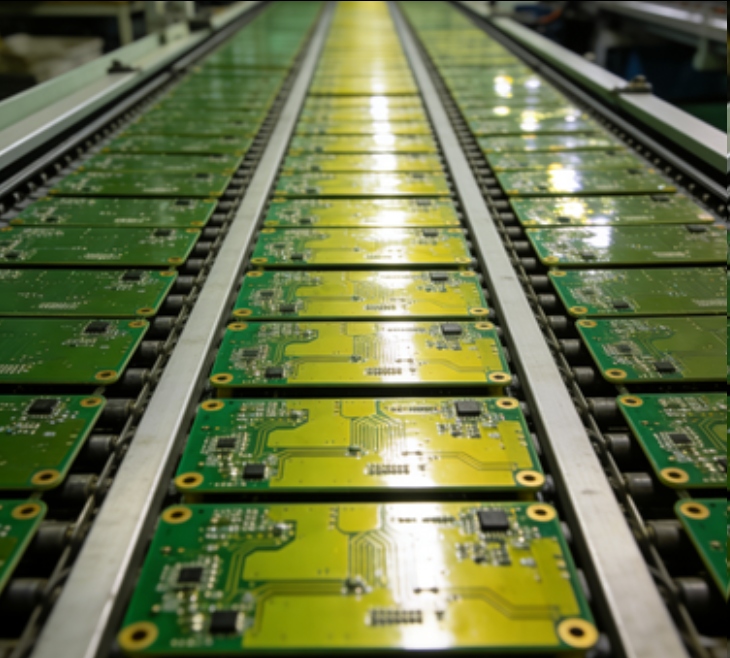

Printed Circuit Boards (PCBs) with Organic Solderability Preservatives (OSP) surface finish have gained significant popularity in the electronics manufacturing industry due to their unique properties and advantages. OSP is a thin, transparent organic coating applied to the copper surfaces of PCBs, primarily serving to protect the copper from oxidation and enhance its solderability during the assembly process.

The OSP coating is typically applied through a chemical immersion process. First, the PCB undergoes a thorough cleaning to remove any contaminants, such as oils, dirt, or oxides, from the copper surface. This cleaning step is crucial as any impurities can interfere with the adhesion and performance of the OSP coating. After cleaning, the PCB is immersed in a bath containing the OSP solution. The solution reacts with the copper surface, forming a very thin, molecular - level organic film. This film acts as a barrier, preventing oxygen and moisture from reaching the copper and thus inhibiting oxidation.

One of the key benefits of OSP surface finish is its ultra - thin nature. Compared to other surface finishing methods like electroless nickel - immersion gold (ENIG) or hot - air solder leveling (HASL), OSP coatings are much thinner, usually in the range of 0.2 - 0.5 micrometers. This thinness allows for better compatibility with fine - pitch components, enabling more precise soldering and reducing the risk of solder bridging between closely - spaced pads. In high - density PCBs where component sizes are getting smaller and pad pitches are becoming finer, the use of OSP can significantly improve the assembly yield and overall reliability of the PCB.

Another advantage of OSP is its cost - effectiveness. The application process of OSP is relatively simple and requires less equipment and chemicals compared to more complex surface finishing techniques. Additionally, since OSP coatings are thin, they consume fewer materials, further reducing production costs. This makes PCBs with OSP surface finish an attractive option for mass - production applications where cost control is a critical factor.

However, PCBs with OSP surface finish also have some limitations. The OSP coating is relatively fragile and can be easily damaged during handling or storage if not properly protected. It has a limited shelf life, and exposure to high humidity or long - term storage can degrade the coating's performance, reducing its solderability. To mitigate these issues, proper handling procedures, such as using anti - static packaging and storing PCBs in a controlled - humidity environment, are essential. Despite these limitations, the benefits of OSP surface finish, including its thinness, cost - effectiveness, and good solderability, make it a widely used choice for many electronics applications, especially in consumer electronics and high - density circuit board designs.