-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-17 Views:1

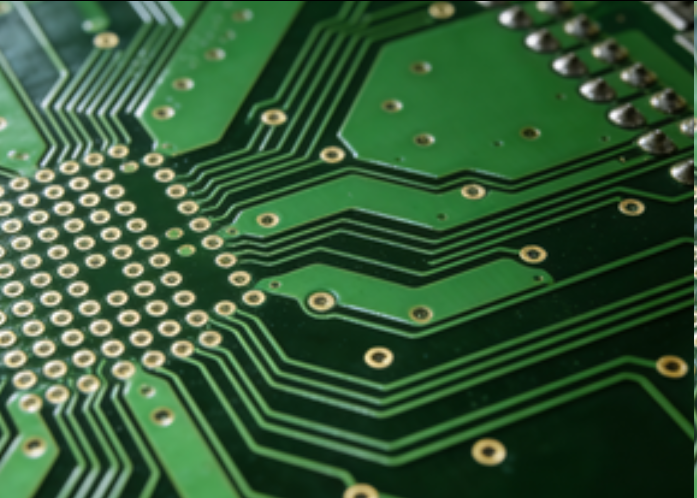

Printed Circuit Boards (PCBs) with uniform solder mask coverage are essential for ensuring the reliability, durability, and functionality of electronic devices. The solder mask, a thin layer of polymer coating applied over the PCB, serves multiple critical purposes, and its uniform application is of utmost importance.

The primary function of the solder mask is to prevent unwanted soldering between conductive traces on the PCB. In a complex PCB layout with numerous closely - spaced traces, even a small amount of solder bridging can lead to short circuits, rendering the PCB and the entire electronic device inoperable. A uniformly applied solder mask creates a barrier that precisely defines the areas where soldering should occur, such as on pads for component attachment, while protecting the rest of the traces. To achieve this uniform coverage, advanced manufacturing techniques are employed.

One common method is screen printing, where a stencil (screen) with the desired solder mask pattern is used. The solder mask ink is forced through the open areas of the screen onto the PCB surface. For uniform coverage, factors such as the mesh count of the screen, the viscosity of the ink, and the pressure and speed during the printing process must be carefully controlled. A higher - quality screen with a finer mesh can deposit the solder mask more evenly, while the right ink viscosity ensures smooth spreading without excessive pooling or thinning. Additionally, automated screen - printing machines with precise motion control systems can consistently apply the solder mask across multiple PCBs, minimizing variations in coverage.

Another technique is spray coating, which is particularly useful for complex or irregularly - shaped PCBs. In this process, the solder mask material is atomized into fine droplets and sprayed onto the PCB surface. The spray nozzles are carefully positioned and adjusted to ensure even distribution of the droplets, and the speed and direction of the spray are optimized to cover the entire PCB uniformly. After application, the solder mask is cured, usually through a process of exposure to ultraviolet (UV) light or heat, which hardens the material and enhances its protective properties.

Quality control is crucial to ensure that the solder mask coverage is indeed uniform. Visual inspection, often with the aid of microscopes or automated optical inspection (AOI) systems, is performed to check for any thin spots, thick patches, or missing areas of the solder mask. Thickness measurements can also be taken at various points on the PCB using instruments like eddy - current thickness gauges or X - ray fluorescence (XRF) analyzers. A PCB with uniform solder mask coverage not only functions reliably but also has a longer lifespan, as it is better protected against environmental factors such as moisture, dust, and chemical corrosion, all of which can damage the underlying conductive traces if the solder mask is uneven or incomplete.