-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-27 Views:1

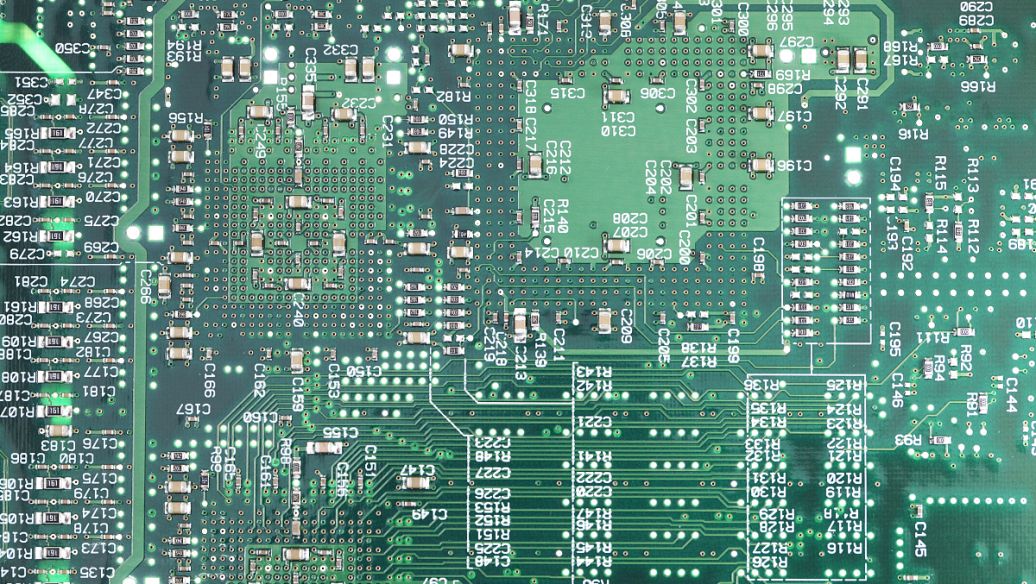

Photovoltaic PCBs are specialized circuit boards designed to support the efficient operation of solar panels and their associated systems. These PCBs serve as the central hub for connecting solar cells, inverters, and monitoring devices, playing a critical role in converting sunlight into usable electricity while ensuring system reliability.

Constructed to withstand harsh outdoor conditions, PV PCBs are made from high-temperature resistant materials such as FR-4 with enhanced glass transition temperatures (Tg) of 150°C or higher, enabling them to endure prolonged exposure to direct sunlight and extreme temperature fluctuations. They often feature thick copper traces (2-3 oz) to handle the high currents generated by solar arrays, minimizing power loss and ensuring efficient energy transfer. Additionally, PV PCBs are coated with conformal coatings or solder masks that provide resistance to moisture, UV radiation, and corrosion—essential for longevity in environments with rain, humidity, or salt spray (e.g., coastal installations).

Design considerations for PV PCBs include optimized layout to reduce parasitic resistance and inductance, which can degrade performance. They integrate connectors for easy installation and maintenance, as well as protection components like fuses and transient voltage suppressors (TVS) to shield against voltage spikes from lightning or grid fluctuations. Many modern PV PCBs also incorporate smart monitoring features, with embedded sensors and communication modules that track energy output, temperature, and fault conditions, enabling remote system management.

As the demand for renewable energy grows, PV PCBs continue to evolve, with advancements in miniaturization and thermal management allowing for higher power densities. Their reliability directly impacts the overall efficiency and lifespan of solar energy systems, making them a foundational component in the global transition to clean energy.