-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-06-16 Views:1

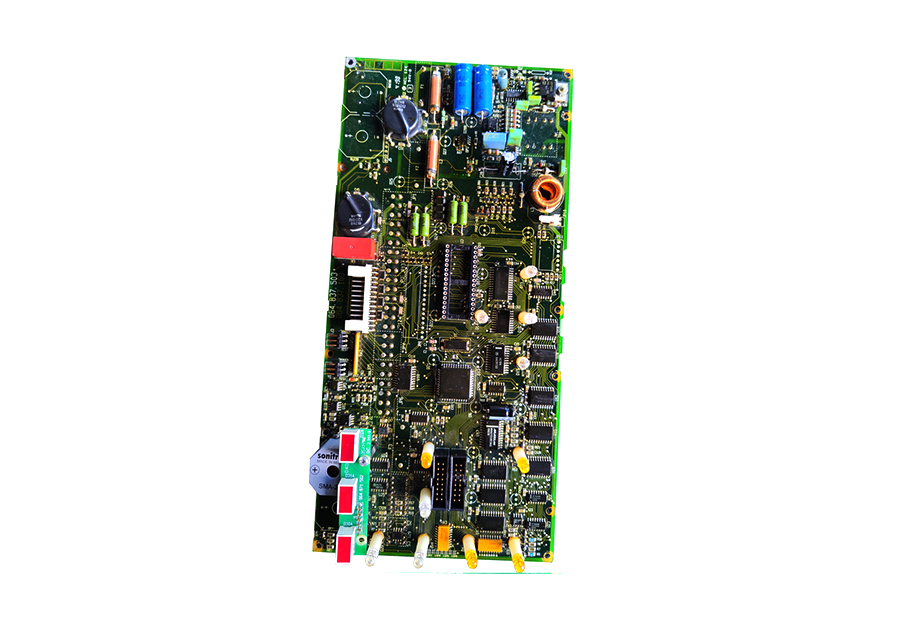

Circuit board assembly is a critical process that requires careful attention to detail to ensure the reliability and functionality of the final product. Whether assembling single-sided or multi-sided PCBs, several key precautions should be taken to avoid errors and defects.

First and foremost, proper handling of components is essential. Electronic components are often delicate and sensitive to static electricity, mechanical stress, and temperature. When handling components, it is necessary to use anti-static wrist straps or mats to prevent static discharge, which can damage sensitive integrated circuits and other components. Components should be picked up and placed gently, avoiding any excessive force that could bend leads or break packages. Additionally, storing components in a controlled environment, away from moisture, dust, and extreme temperatures, helps maintain their integrity until assembly.

Accurate placement of components on the PCB is another crucial aspect. Even a slight misplacement can lead to electrical failures or poor performance. Automated pick-and-place machines are commonly used in large-scale production for high precision. However, in manual assembly, using a magnifying glass or microscope can assist in precisely positioning components according to the design layout. Components should be placed in the correct orientation, especially those with polarity markings, such as diodes, electrolytic capacitors, and integrated circuits. A wrong orientation can cause the component to malfunction or even damage the circuit board.

Soldering is a key step in circuit board assembly, and it requires proper technique and materials. Using the right type of solder with the appropriate melting point and flux content is important. Excessive soldering can create solder bridges between adjacent traces, causing short circuits, while insufficient soldering may result in cold joints, which are weak electrical connections. The soldering iron should be maintained at the correct temperature, typically between 300 - 350°C, and used with a proper tip size for the component being soldered. After soldering, it is necessary to inspect the joints for quality, looking for smooth, shiny surfaces without any voids or spatter.

Testing the assembled circuit board is an indispensable precaution. A thorough electrical test should be conducted to check for short circuits, open circuits, and proper component functionality. This can be done using multimeters, oscilloscopes, or specialized circuit board testers. In addition, functional testing, where the board is integrated into the overall system and tested under real-world operating conditions, helps identify any potential issues that may not be apparent during basic electrical testing. By following these precautions during circuit board assembly, manufacturers can produce high-quality, reliable circuit boards that meet the required specifications.