-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-09 Views:1

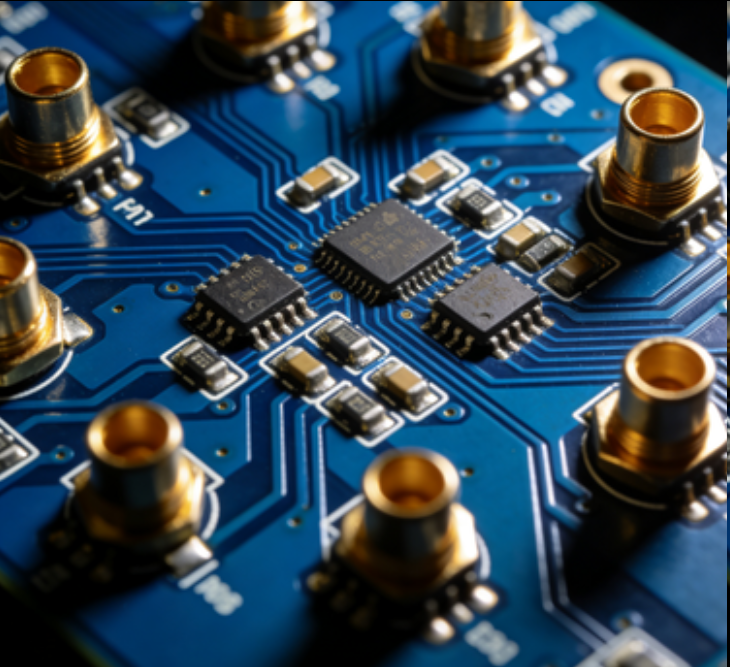

Printed Circuit Boards dedicated to audio circuits are meticulously crafted to meet the unique and demanding requirements of audio signal processing, amplification, and transmission. Audio circuits deal with a wide range of frequencies, from low - frequency bass sounds to high - frequency treble tones, and any interference, distortion, or signal degradation can significantly impact the quality of the audio output. Therefore, the design of PCBs for audio circuits requires a deep understanding of audio engineering principles, precise component selection, and careful layout planning.

One of the key considerations in designing audio - dedicated PCBs is minimizing electromagnetic interference (EMI) and radio - frequency interference (RFI). Audio signals are highly sensitive to external electrical noise, which can manifest as unwanted hums, hisses, or static in the audio output. To combat this, PCBs for audio circuits often incorporate shielding techniques. Ground planes are used extensively to provide a low - impedance path for electrical noise, while metal shields can be added to isolate sensitive audio components from external interference sources. Additionally, proper trace routing is crucial. Audio traces are typically routed separately from high - frequency digital or power traces to prevent crosstalk, ensuring that each audio signal remains pure and undistorted as it travels through the PCB.

The selection of substrate materials for audio PCBs is also important. Materials with low dielectric loss and stable electrical properties are preferred to minimize signal attenuation and phase distortion. For example, fiberglass - based substrates like FR4 are commonly used due to their good balance of cost, performance, and availability. However, for high - end audio applications where the utmost sound quality is required, specialized substrates with even lower loss characteristics may be chosen. These materials help maintain the integrity of the audio signal, ensuring that the subtlest nuances of the sound are accurately reproduced.

Component placement on audio PCBs is carefully planned to optimize signal flow and reduce signal delays. Audio - processing components such as operational amplifiers, audio codecs, and analog - to - digital converters (ADCs) are placed in close proximity to the relevant input and output signals. This reduces the length of the audio traces, minimizing the potential for signal degradation. Moreover, proper decoupling capacitors are strategically placed near power - hungry components to filter out any electrical noise on the power supply lines, ensuring a clean and stable power source for the audio circuit. With their specialized design and attention to the unique requirements of audio circuits, these PCBs are essential for delivering high - fidelity audio performance in a variety of applications, from home audio systems and professional audio equipment to automotive infotainment systems.