-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-09-25 Views:1

Rigid - flex PCBs (Printed Circuit Boards) represent a revolutionary advancement in PCB technology, combining the benefits of rigid and flexible PCBs into a single, integrated solution. This unique combination allows for greater design flexibility, space - saving, and enhanced reliability in a wide range of electronic devices.

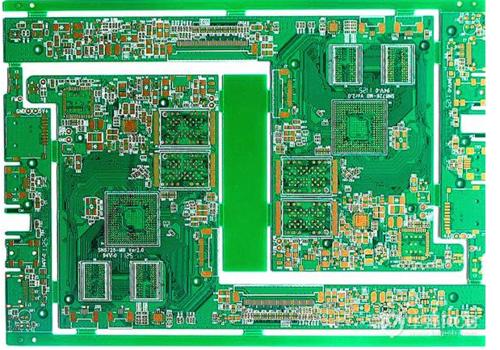

The structure of a rigid - flex PCB is a complex yet carefully engineered assembly. It consists of rigid sections, which provide the necessary mechanical support and stability for components such as integrated circuits, connectors, and other electronic parts. These rigid sections are typically made from traditional PCB materials like fiberglass - reinforced epoxy (FR - 4), which offer good electrical insulation and mechanical strength. Interspersed between the rigid sections are flexible sections, usually fabricated from polyimide or other flexible substrates. These flexible parts are designed to bend, flex, and fold, enabling the PCB to conform to complex shapes and fit into tight spaces within electronic devices.

One of the primary advantages of rigid - flex PCBs is their ability to reduce the overall size and weight of electronic products. By integrating multiple PCB functions into a single rigid - flex board, the need for numerous individual PCBs and interconnecting cables is eliminated. This not only saves valuable space but also reduces the potential for connection failures and signal interference. For example, in aerospace applications, where every ounce of weight and every bit of space matter, rigid - flex PCBs are used in avionics systems to connect various sensors, processors, and communication modules in a compact and efficient manner.

Rigid - flex PCBs also offer enhanced reliability. The elimination of external connectors and cables reduces the risk of mechanical damage, such as bending, pulling, or vibration - induced failures. The integrated design ensures a more stable electrical connection between components, improving signal integrity and reducing the likelihood of electrical issues. In medical devices, where reliability is of utmost importance, rigid - flex PCBs are used in implantable devices, wearable health monitors, and surgical instruments. The ability of these boards to withstand repeated flexing and movement while maintaining electrical performance makes them ideal for these applications.

In addition, rigid - flex PCBs enable more creative and innovative product designs. They can be customized to fit the specific requirements of a device, whether it's a foldable smartphone, a robotic arm, or a complex industrial control system. The flexibility of the board allows for unique form factors and enables designers to optimize the layout of components for better performance and functionality. Overall, rigid - flex PCBs have become an essential technology in modern electronics, offering a combination of flexibility, reliability, and space - saving benefits that are crucial for the development of advanced electronic devices.