-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-12-26 Views:1

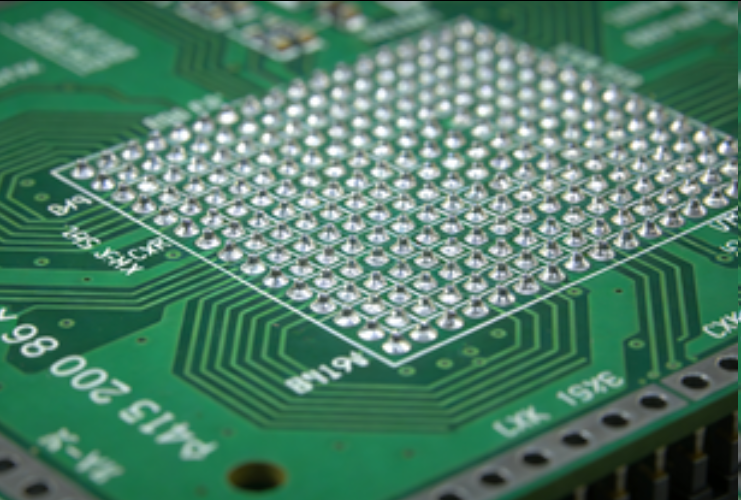

Rigid PCBs (Rigid Printed Circuit Boards) are circuit boards with a rigid, inflexible substrate—typically made of FR-4 (fiberglass-reinforced epoxy resin), ceramic, or metal-core materials—designed to maintain their shape in fixed electronic assemblies. Unlike flexible PCBs (which bend to fit tight spaces), rigid PCBs prioritize structural stability and mechanical strength, making them ideal for devices where the circuit board does not need to flex or conform to irregular shapes.

The core advantage of rigid PCBs lies in mechanical stability: their rigid substrate provides a sturdy base for mounting components (e.g., heavy microchips, transformers, or connectors) without warping or deformation, even under thermal stress or vibration. FR-4, the most common rigid substrate, offers a balance of cost, insulation, and thermal resistance—suitable for a wide range of applications, from consumer electronics to industrial equipment. For high-heat environments (e.g., power supplies or automotive engine control units), metal-core rigid PCBs (with aluminum or copper cores) enhance heat dissipation, preventing component overheating.

Rigid PCBs are available in single-sided, double-sided, or multi-layer configurations, catering to varying complexity needs. For example, a single-sided rigid PCB powers a basic alarm clock, while a 12-layer rigid PCB supports the complex circuitry of a laptop motherboard. Key features include high component density compatibility (supporting surface-mount and through-hole components of all sizes) and ease of manufacturing (standardized production processes reduce costs for high-volume orders). They also offer excellent dimensional stability—critical for precision devices like medical monitors, where component alignment directly impacts performance.

Practical applications span nearly every industry: rigid PCBs are the backbone of smartphones (as the main logic board), televisions (power and signal processing boards), industrial controllers (for factory automation), and automotive infotainment systems. While they lack the flexibility of flexible PCBs, their durability and stability make them the go-to choice for fixed electronic assemblies. For manufacturers seeking reliable, cost-effective circuit boards for non-flexible applications, rigid PCBs deliver consistent performance and long-term reliability.