-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2026-01-14 Views:1

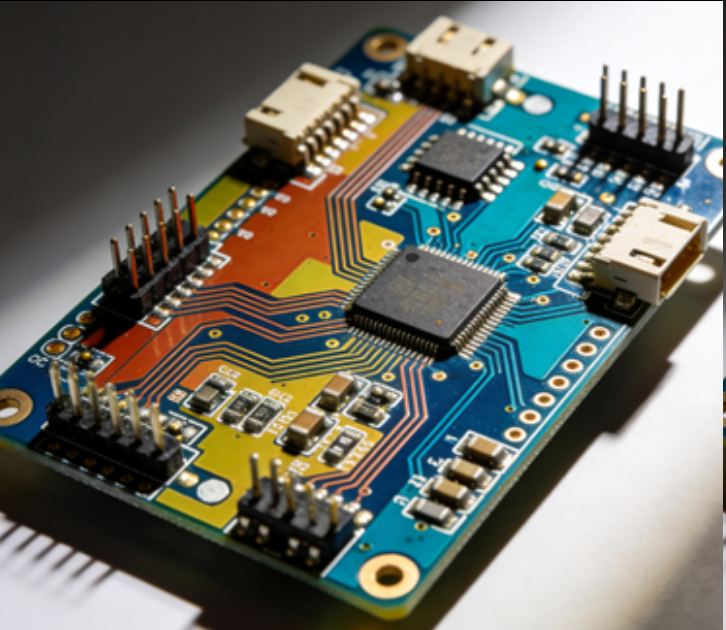

Small - batch customized PCB circuit boards have emerged as a crucial solution in the electronics industry, catering to a wide range of needs from startups and small - scale manufacturers to research institutions and hobbyists. Unlike mass - produced PCBs, small - batch customized PCBs are tailored to specific requirements, offering flexibility and the ability to incorporate unique design elements, functionality, and form factors.

The process of creating small - batch customized PCBs begins with in - depth communication between the customer and the PCB manufacturer. Customers provide detailed specifications, including circuit schematics, component placement requirements, and any special performance or environmental considerations. Designers then use specialized software, such as Altium Designer or Eagle, to translate these requirements into a PCB layout. In this stage, they carefully consider factors like trace routing, layer stack - up, and impedance control to ensure the PCB meets the electrical performance criteria. For example, if the PCB is intended for a high - frequency application, designers will focus on minimizing signal interference and ensuring proper impedance matching to prevent signal degradation.

One of the key advantages of small - batch customized PCBs is the opportunity for rapid prototyping and product development. Startups often need to quickly test and iterate their electronic designs. Small - batch production allows them to obtain a limited number of PCBs for initial testing, enabling them to identify and fix any design flaws before committing to large - scale manufacturing. Additionally, for products with unique or specialized requirements, such as custom - built medical devices or aerospace - specific electronics, small - batch customization ensures that the PCBs precisely meet the functional and dimensional constraints. This is in contrast to off - the - shelf PCBs, which may not be suitable for such niche applications.

Manufacturing small - batch customized PCBs also requires a different approach compared to mass production. Specialized equipment and skilled technicians are employed to handle the unique designs. Advanced manufacturing techniques, like laser drilling for micro - vias and high - precision etching for fine - pitch traces, are used to achieve the required accuracy. Quality control is of utmost importance, with each PCB undergoing rigorous testing, including electrical testing, visual inspection, and in some cases, X - ray inspection to detect hidden defects. Although the per - unit cost of small - batch customized PCBs is generally higher than that of mass - produced ones due to setup costs and lower economies of scale, the value lies in the ability to meet specific needs, reduce development time, and minimize the risk of large - scale production failures. As the electronics industry continues to innovate with diverse product requirements, small - batch customized PCB circuit boards will remain an essential part of the product development and manufacturing ecosystem.