-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-26 Views:1

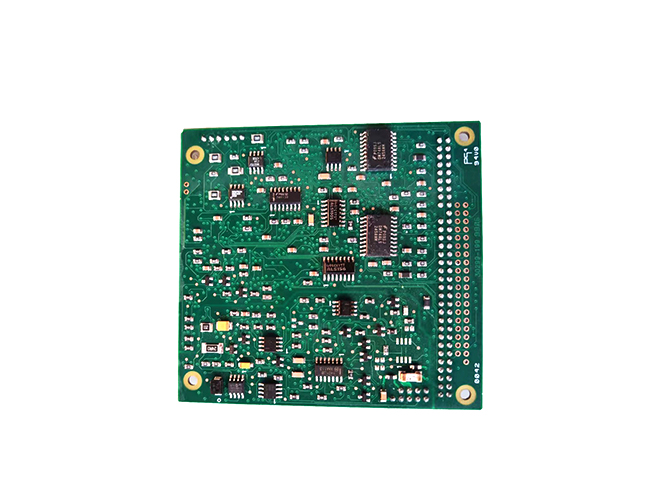

High-voltage PCBs are used in applications such as power supplies, electric vehicles, and high-voltage testing equipment. Their structural design needs to ensure electrical safety, mechanical strength, and reliable performance.

One of the primary considerations in high-voltage PCB design is electrical insulation. The distance between high-voltage traces and other components or ground planes needs to be carefully calculated to prevent electrical breakdown. This is known as the creepage distance, which is the shortest distance along the surface of the insulation material between two conductive parts. Additionally, the clearance distance, which is the shortest air distance between two conductive parts, also needs to be sufficient. Insulating materials with high dielectric strength, such as FR-4 with a higher CTI (Comparative Tracking Index) rating, are often used in high-voltage PCBs.

The layout of high-voltage traces should be designed to minimize the risk of arcing. Traces should be routed in a straight line as much as possible, avoiding sharp corners or bends, which can cause electric field concentration. Large pads and vias should be used for high-voltage connections to reduce the current density and prevent overheating. In addition, the use of barrier strips or isolation slots can be effective in separating high-voltage and low-voltage sections of the PCB.

Mechanical strength is also crucial for high-voltage PCBs. Since high-voltage applications often involve large currents and power levels, the PCB needs to be able to withstand the associated mechanical stresses. Thicker PCB substrates and additional support structures, such as metal stiffeners, can be used to enhance the mechanical strength. The mounting holes on the PCB should be designed to securely fasten the board in the enclosure, preventing any movement that could cause damage to the high-voltage components or traces.

Thermal management is another important aspect of high-voltage PCB design. High-voltage components, such as power transistors and diodes, can generate a significant amount of heat. Proper heat dissipation mechanisms, such as heat sinks or vias for thermal conduction, need to be incorporated into the design. The layout of components should also consider the airflow within the enclosure to ensure efficient heat transfer.