-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Time:2025-04-28 Views:1

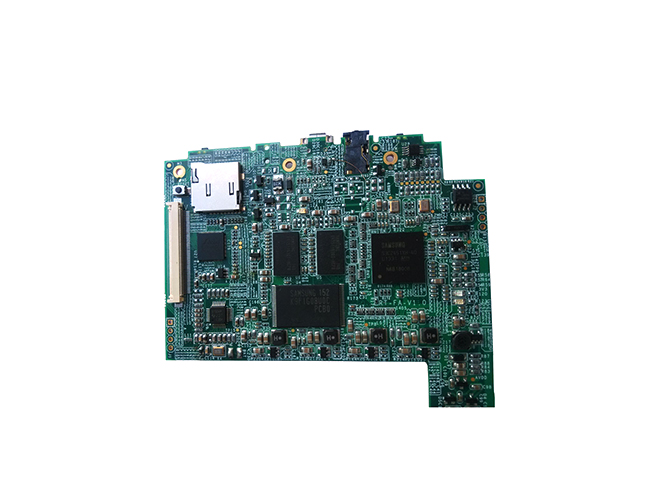

Proper transportation packaging of PCBA boards is crucial to ensure that they arrive at their destination in good condition. Given the delicate nature of PCBA boards, with their sensitive electronic components and intricate circuitry, specific packaging requirements must be met.

Anti - static Protection

PCBA boards are highly sensitive to static electricity, which can cause damage to the components. Therefore, anti - static packaging materials are essential. Anti - static bags are commonly used to enclose the PCBA boards. These bags are designed to prevent the build - up and transfer of static charges. Some anti - static bags also have a moisture - barrier property, which is an added advantage. In addition to bags, anti - static foam or padding can be used to surround the boards. This foam helps to cushion the boards during transportation and also provides anti - static protection.

Moisture Protection

Moisture can also cause significant damage to PCBA boards, especially if it leads to corrosion of the components or short - circuits. To protect against moisture, moisture - proof packaging materials should be used. This can include sealed plastic enclosures or boxes with a high - quality seal. Desiccant packets can be placed inside the packaging to absorb any moisture that may be present. These packets typically contain silica gel or other moisture - absorbing substances. For PCBA boards with particularly moisture - sensitive components, additional measures such as vacuum - sealing the packaging may be necessary.

Shock and Vibration Protection

During transportation, PCBA boards are exposed to various levels of shock and vibration, which can dislodge components or damage the circuitry. To mitigate these risks, shock - absorbing materials are used. Bubble wrap, air - filled cushions, or foam inserts can be used to surround the PCBA boards and provide cushioning. The packaging should be designed in such a way that it can withstand normal handling and transportation - related shocks without the boards being affected. Additionally, the boards should be securely fastened within the packaging to prevent them from moving around and getting damaged.

Labeling Requirements

Proper labeling of the PCBA board packaging is important for identification and handling. The packaging should clearly indicate the contents, including the type of PCBA board, its model number, and any special handling instructions. For example, if the board is particularly sensitive to temperature or humidity, this should be clearly labeled. Labels should also include information about the manufacturer, the destination, and any relevant safety warnings, such as the presence of anti - static or moisture - sensitive materials.