-

CN

-

Service Hotline

+8618129931046 Mr. Liao

Rigid - flex composite PCB circuit boards represent a revolutionary advancement in printed circuit board technology, combining the benefits of rigid and flexible PCBs to meet the complex requirements of modern electronic devices. These boards integrate rigid sections, which provide structural stabil

Jan 13, 2026

Jan 13, 2026

1

1

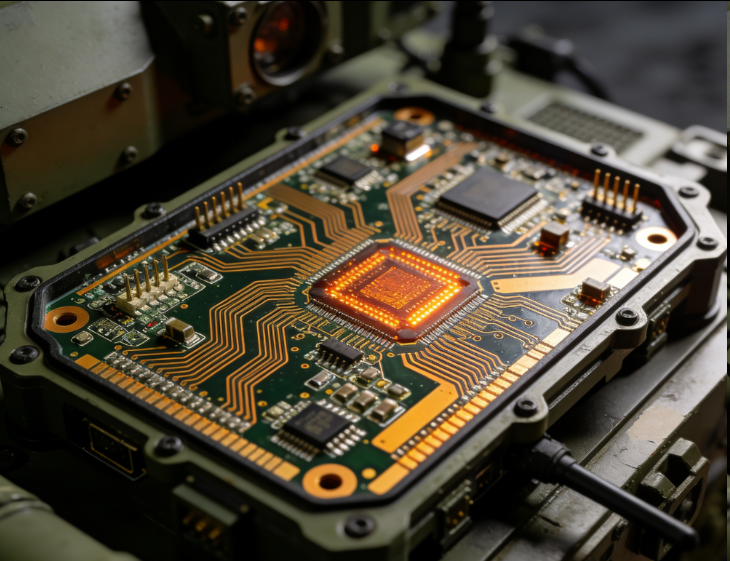

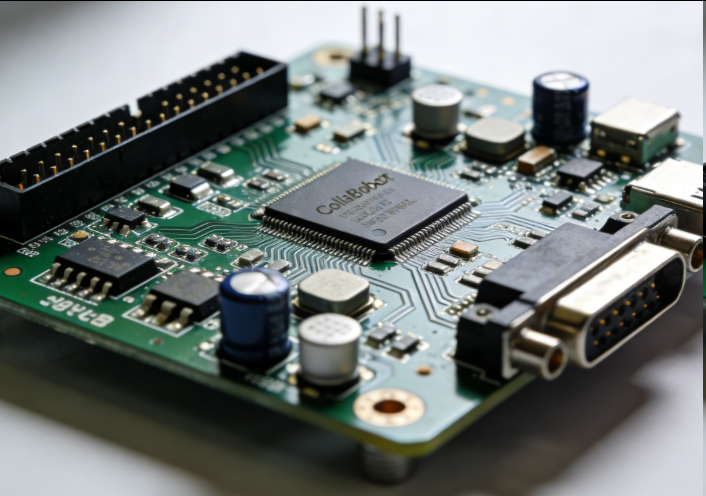

Collaborative robots, or cobots, are designed to work alongside humans in various industrial and non - industrial settings, requiring a high level of safety, precision, and flexibility. The dedicated PCB boards for collaborative robots play a pivotal role in enabling these characteristics, serving a

Jan 12, 2026

Jan 12, 2026

1

1

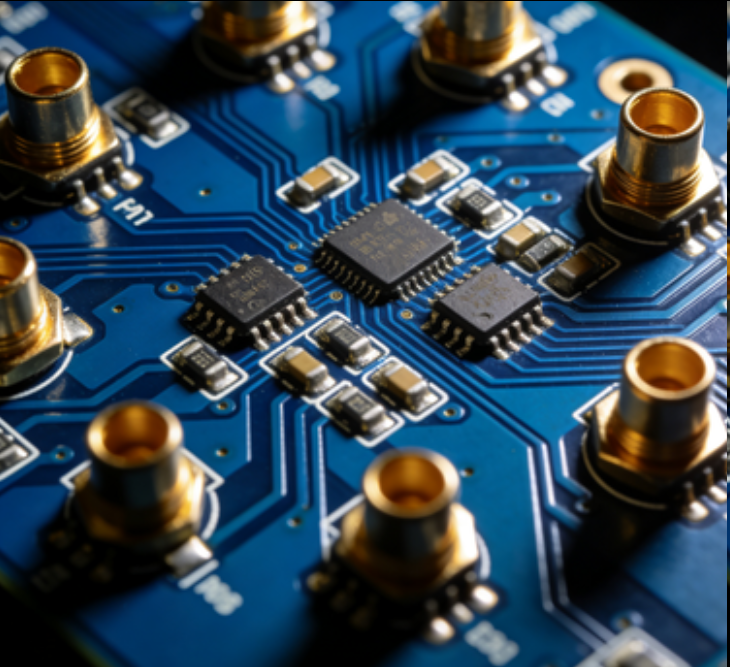

Printed Circuit Boards dedicated to audio circuits are meticulously crafted to meet the unique and demanding requirements of audio signal processing, amplification, and transmission. Audio circuits deal with a wide range of frequencies, from low - frequency bass sounds to high - frequency treble to

Jan 09, 2026

Jan 09, 2026

1

1

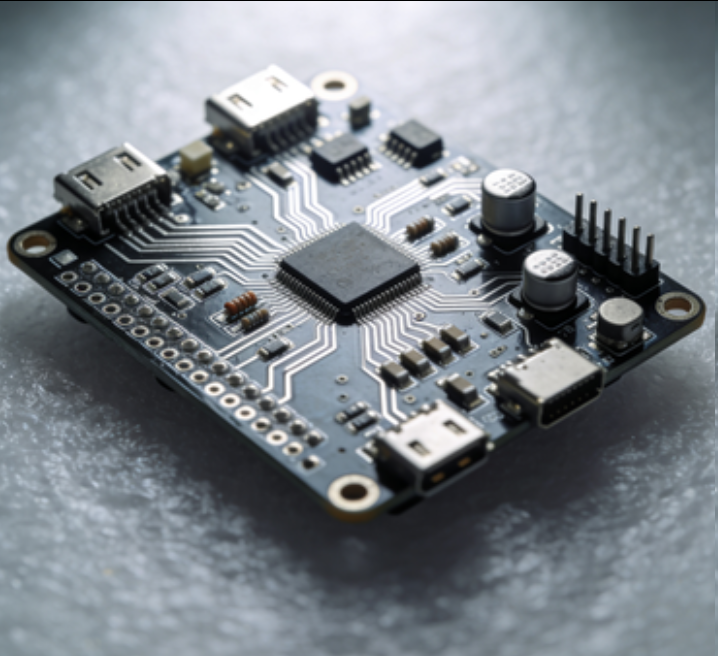

Printed Circuit Boards (PCBs) adapted for smart home applications are the key enablers behind the seamless operation and connectivity of various intelligent devices within modern households. These PCBs are engineered to meet the unique requirements of smart home systems, which demand a combination o

Jan 07, 2026

Jan 07, 2026

1

1

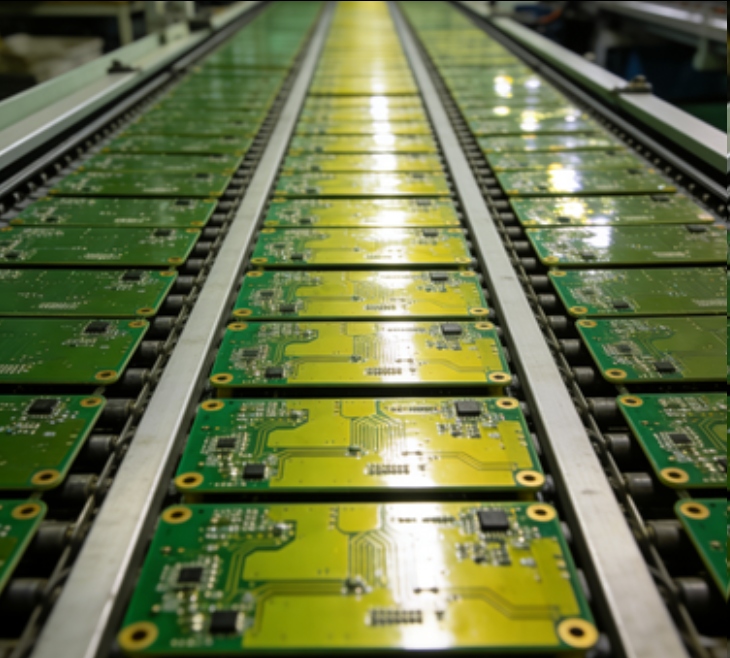

Printed Circuit Boards (PCBs) with Organic Solderability Preservatives (OSP) surface finish have gained significant popularity in the electronics manufacturing industry due to their unique properties and advantages. OSP is a thin, transparent organic coating applied to the copper surfaces of PCB

Jan 06, 2026

Jan 06, 2026

1

1

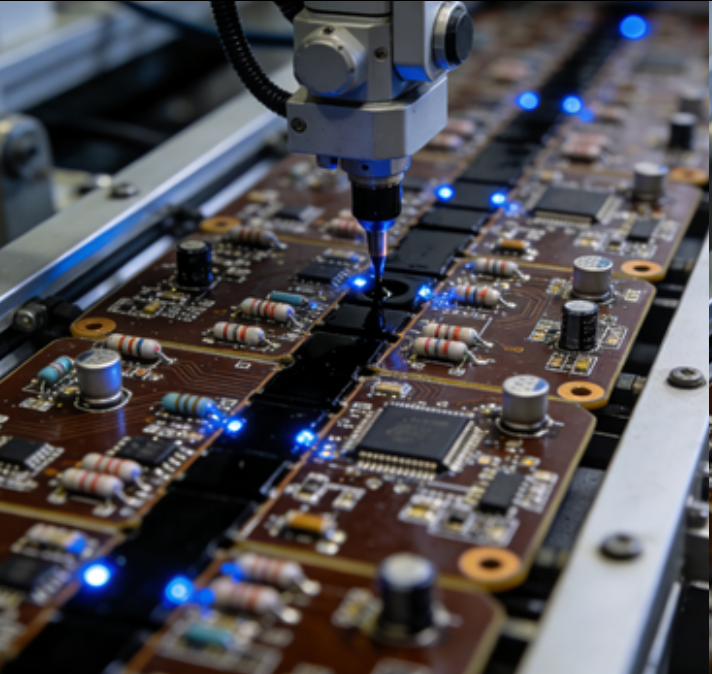

Spray painting robots are extensively utilized in industries like automotive manufacturing, furniture production, and metal finishing, where consistent and high - quality coating is essential. The PCB boards compatible with spray painting robots are meticulously engineered to meet the unique demands

Jan 05, 2026

Jan 05, 2026

1

1